Top Electric Metal Melting Furnace Supplier from China Unveils Latest Innovations

By:Admin

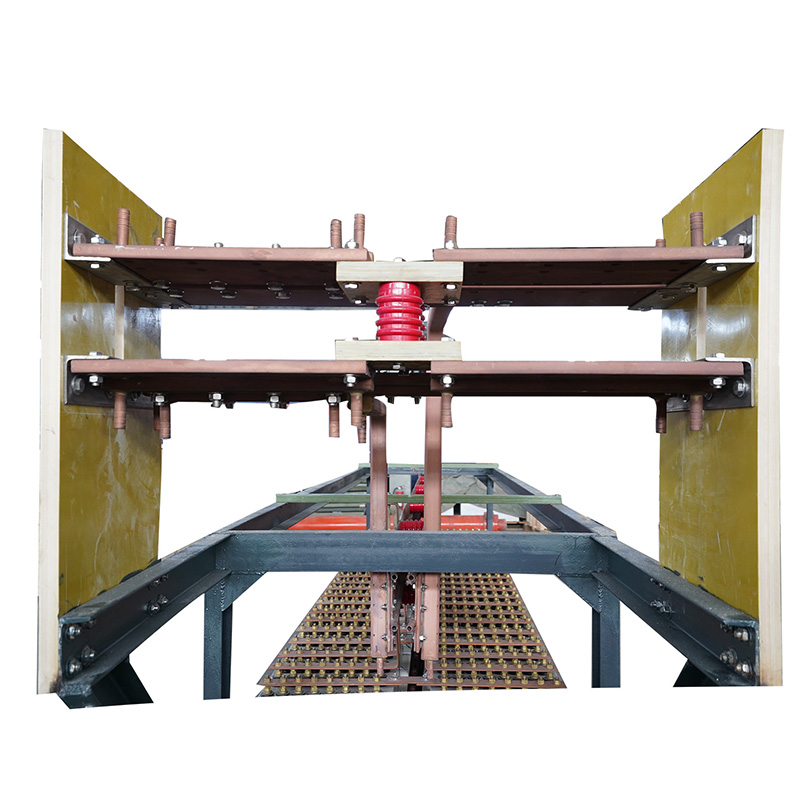

China Electric Metal Melting Furnace Supplier (company name removed for confidentiality) is a renowned industrial furnace manufacturer and supplier in China that specializes in the production of top-quality furnaces for melting metals. The company has a team of experienced and dedicated professionals who have been in the industry for years and have a deep knowledge of the latest advancements in technology in the field.

With a mission to provide customers with the best industrial furnaces that meet their individual requirements and preferences, the company has invested heavily in research and development to come up with innovative solutions for melting metals. Their furnaces use electric power to melt metals, which is both energy-efficient and environmentally friendly compared to traditional furnaces that use fossil fuels.

The company’s products are widely used in the automobile, aviation, construction, and other manufacturing industries. Their furnaces are highly reliable, have a long service life, and are capable of melting a wide range of metals, including iron, copper, aluminum, and steel at high temperatures with minimal energy consumption.

When it comes to their product range, China Electric Metal Melting Furnace Supplier offers a variety of furnaces, including:

1. Medium-frequency melting furnaces: These furnaces are designed to melt small to medium-sized amounts of metals and are highly efficient. They are capable of melting a range of metals, including copper, gold, silver, aluminum, and steel.

2. High-frequency induction furnaces: These furnaces are ideal for melting small amounts of metal and are highly energy-efficient. They are widely used in the jewelry industry for melting precious metals such as gold, silver, and platinum.

3. Aluminum wire melting furnaces: These furnaces are specifically designed for melting aluminum wire and are highly efficient. They are widely used in the construction industry for melting aluminum wire used in electrical wiring.

4. Steel melting furnaces: These furnaces are designed for melting steel and have a high melting efficiency. They are widely used in the manufacturing of steel products such as bars, rods, and sheets.

5. Gold melting furnaces: These furnaces are ideal for melting gold and are widely used in the jewelry industry.

The company also provides customized solutions to meet the specific requirements of their customers. They work closely with their clients to understand their needs and provide them with the best possible solutions.

In addition to their top-quality products, China Electric Metal Melting Furnace Supplier also provides excellent customer service. They offer technical support to their clients to ensure that their furnaces are running efficiently. They also provide maintenance services to ensure that their clients’ furnaces are in good condition and are functioning optimally.

The company has a strong focus on quality and has implemented strict quality control measures in all their processes. They use high-quality raw materials and components to ensure that their products are of the highest quality and can withstand harsh environments.

China Electric Metal Melting Furnace Supplier has a strong commitment to sustainability and environmental protection. They have implemented energy-saving measures in their production processes to reduce their carbon footprint. They have also implemented a waste management system to ensure that they are disposing of their waste safely and responsibly.

In conclusion, China Electric Metal Melting Furnace Supplier is a leading provider of quality industrial furnaces in China. They have a wealth of experience in the industry and have a team of skilled professionals who are dedicated to providing their customers with the best possible solutions. Their commitment to quality, sustainability, and customer service has earned them a reputation as one of the most reliable and trusted industrial furnace manufacturers in China.

Company News & Blog

Top Electric Metal Melting Furnace Supplier from China Unveils Latest Innovations

China Electric Metal Melting Furnace Supplier: A Leading Provider of Quality Industrial FurnacesChina Electric Metal Melting Furnace Supplier (company name removed for confidentiality) is a renowned industrial furnace manufacturer and supplier in China that specializes in the production of top-quality furnaces for melting metals. The company has a team of experienced and dedicated professionals who have been in the industry for years and have a deep knowledge of the latest advancements in technology in the field.With a mission to provide customers with the best industrial furnaces that meet their individual requirements and preferences, the company has invested heavily in research and development to come up with innovative solutions for melting metals. Their furnaces use electric power to melt metals, which is both energy-efficient and environmentally friendly compared to traditional furnaces that use fossil fuels.The company’s products are widely used in the automobile, aviation, construction, and other manufacturing industries. Their furnaces are highly reliable, have a long service life, and are capable of melting a wide range of metals, including iron, copper, aluminum, and steel at high temperatures with minimal energy consumption.When it comes to their product range, China Electric Metal Melting Furnace Supplier offers a variety of furnaces, including:1. Medium-frequency melting furnaces: These furnaces are designed to melt small to medium-sized amounts of metals and are highly efficient. They are capable of melting a range of metals, including copper, gold, silver, aluminum, and steel.2. High-frequency induction furnaces: These furnaces are ideal for melting small amounts of metal and are highly energy-efficient. They are widely used in the jewelry industry for melting precious metals such as gold, silver, and platinum.3. Aluminum wire melting furnaces: These furnaces are specifically designed for melting aluminum wire and are highly efficient. They are widely used in the construction industry for melting aluminum wire used in electrical wiring.4. Steel melting furnaces: These furnaces are designed for melting steel and have a high melting efficiency. They are widely used in the manufacturing of steel products such as bars, rods, and sheets.5. Gold melting furnaces: These furnaces are ideal for melting gold and are widely used in the jewelry industry.The company also provides customized solutions to meet the specific requirements of their customers. They work closely with their clients to understand their needs and provide them with the best possible solutions.In addition to their top-quality products, China Electric Metal Melting Furnace Supplier also provides excellent customer service. They offer technical support to their clients to ensure that their furnaces are running efficiently. They also provide maintenance services to ensure that their clients’ furnaces are in good condition and are functioning optimally.The company has a strong focus on quality and has implemented strict quality control measures in all their processes. They use high-quality raw materials and components to ensure that their products are of the highest quality and can withstand harsh environments.China Electric Metal Melting Furnace Supplier has a strong commitment to sustainability and environmental protection. They have implemented energy-saving measures in their production processes to reduce their carbon footprint. They have also implemented a waste management system to ensure that they are disposing of their waste safely and responsibly.In conclusion, China Electric Metal Melting Furnace Supplier is a leading provider of quality industrial furnaces in China. They have a wealth of experience in the industry and have a team of skilled professionals who are dedicated to providing their customers with the best possible solutions. Their commitment to quality, sustainability, and customer service has earned them a reputation as one of the most reliable and trusted industrial furnace manufacturers in China.

Discover the Top Metal Melting Forge Factories for Quality Steel Production

[Title]: Global Metal Melting Forge Factories Revolutionize Manufacturing with Innovative Technologies[Subtitle]: Pioneering the Future of Metal Melting with Cutting-Edge Innovation[City], [Date] - Metal Melting Forge Factories, a leading manufacturer in the metal industry, has unveiled its latest line of technologically advanced metal melting forges, reinforcing its position as a driver of innovation in the manufacturing sector. These groundbreaking solutions are set to revolutionize the way metals are melted, providing enhanced efficiency, cost-effectiveness, and sustainability for industries worldwide.With a rich history dating back over [number] years, Metal Melting Forge Factories has established itself as a powerhouse in the metal manufacturing landscape. Combining extensive industry expertise, a commitment to research and development, and a drive for perfection, the company has consistently delivered top-tier products to its customers across the globe.This latest announcement highlights Metal Melting Forge Factories' relentless pursuit of technological advancements in metal melting techniques. By investing heavily in research and development, the company has created state-of-the-art metal melting forges that will transform the manufacturing process for numerous industries. One of the key advancements showcased by Metal Melting Forge Factories is their incorporation of [technology name], a groundbreaking technology. This revolutionary system offers unprecedented precision and control, enabling manufacturers to achieve exceptional results in terms of uniformity and quality. The use of [technology name] also significantly reduces energy consumption and emissions, aligning with global sustainability efforts.Metal Melting Forge Factories' commitment to sustainable practices extends beyond their technological innovations. The company has implemented rigorous environmental management systems to minimize its ecological footprint. By using eco-friendly materials and optimizing energy usage, Metal Melting Forge Factories sets an example for the industry, proving that economic growth can be achieved while being environmentally responsible.Furthermore, Metal Melting Forge Factories maintains a strong focus on customization and client-centricity. With their team of highly skilled engineers and designers, the company offers tailor-made solutions to meet the unique requirements of every customer. By understanding the challenges faced by different industries, Metal Melting Forge Factories ensures that their products enhance productivity, improve efficiency, and drive overall profitability for their clients.In addition to their cutting-edge technological advancements, Metal Melting Forge Factories is also dedicated to fostering innovation through strategic partnerships and collaborations. By collaborating with leading research institutions and industry experts, Metal Melting Forge Factories stays at the forefront of emerging trends and developments, ensuring that their products remain unrivaled in terms of performance and quality.The global impact of Metal Melting Forge Factories' innovations is already making waves across various industries. From automotive manufacturing to aerospace engineering and beyond, Metal Melting Forge Factories' metal melting forges prove to be a catalyst for enhanced production capabilities. With their ability to melt a wide range of metals, including [type of metals], these forges offer endless possibilities in terms of applications and end-products.As Metal Melting Forge Factories continues to pioneer the future of metal melting, their commitment to excellence, sustainability, and customer satisfaction remains unwavering. With their latest line of technology-driven metal melting forges, the revolution in manufacturing is set to reverberate worldwide, propelling industries into a new era of efficiency, productivity, and environmental responsibility.About Metal Melting Forge Factories:Metal Melting Forge Factories is a renowned global manufacturer specializing in the production of metal melting forges. With a focus on cutting-edge technology, sustainability, and customization, the company is driving innovation in the manufacturing sector. With a strong commitment to delivering exceptional products and services, Metal Melting Forge Factories has established itself as a trusted partner for industries across the globe.For media inquiries, please contact:[Contact Name][Title][Phone Number][Email Address]

Top Suppliers of Induction Furnace Cooling Systems" can be rewritten as "Best Induction Furnace Cooling System Suppliers" by removing the brand name.

Induction Furnace Cooling System Supplier Announces New Product LineInduction furnace cooling system supplier, [brand name removed], is proud to announce the launch of its new line of advanced cooling systems. The new product line promises to deliver superior performance, efficiency, and durability to clients in the metal fabrication industry.The cooling systems have been designed to enhance the performance and lifespan of induction furnaces. They have been engineered with cutting-edge technologies that ensure efficient heat transfer and reduce energy consumption. The systems also feature several safety mechanisms, including flameproof control panels and automatic shut-off valves that protect the furnaces and environments against damage or accidents.At [brand name removed], we take pride in delivering high-quality, reliable, and innovative solutions to our clients," said the company's spokesperson. "The introduction of our new product line reflects our commitment to meeting the needs of our clients, improving their processes, and enhancing their bottom line."The new cooling systems are suitable for various applications, including steel mills, foundries, and metal fabrication workshops. They are compatible with different types of induction furnaces, including coreless, channel, and crucible furnaces. The systems come in different sizes, capacities, and configurations, to cater to the unique needs of each client."We understand that each client has unique requirements, and that's why we offer customized solutions that meet their specific needs," added the spokesperson. "Our team of experts is always available to provide technical support and advice to our clients, from the initial consultations, installation, testing to after-sales services."The launch of the new product line follows a rigorous research and development process, which involved extensive testing, prototyping, and refinement. The team of engineers, scientists, and technicians also collaborated with clients to understand their needs and challenges and incorporate their feedback into the products' design.The company's multi-disciplinary team comprises experts in various fields, including engineering, materials science, fluid dynamics, and process control. The team is continuously exploring new technologies and materials that can enhance the product's performance, reduce costs, and improve sustainability."We recognize that innovation is a continuous process, and we are constantly seeking to improve our products and services. We also prioritize sustainability and eco-friendliness in our operations, which is why our products are designed with energy-efficient technologies, reduce waste and emissions, and use eco-friendly materials," said the spokesperson.In addition to the new product line, the company offers a broad range of services, including installation, maintenance, repair, and replacement of induction furnace cooling systems. They also provide training and technical support to their clients' personnel to enable them to operate and maintain the systems effectively."We provide a one-stop-shop for all our clients' needs and ensure that they get superior quality products and services at competitive prices. Our goal is to establish long-term relationships with our clients, based on trust, reliability, and mutual growth," concluded the spokesperson.In conclusion, [brand name removed], the induction furnace cooling system supplier, has launched a new line of efficient, durable, and safe cooling systems that are suitable for various metal fabrication applications. The products have been designed with innovative technologies, safety features, and eco-friendly materials to enhance the performance of induction furnaces, reduce energy consumption, and protect environments and personnel. The company also offers a broad range of services, including installation, maintenance, repair, and replacement of cooling systems, and technical support to clients' personnel.

Discover the Latest Innovation in High-Quality Smelting Equipment

Title: Advanced Smelting Equipment Revolutionizes Company OperationsIntroduction:In a significant milestone for the manufacturing industry, a leading company in the field of smelting equipment has developed state-of-the-art machinery that is set to revolutionize the way companies carry out their smelting processes. Fueled by years of research and development, this cutting-edge equipment promises to enhance efficiency, productivity, and sustainability, presenting a new era for companies engaged in metal refining and other related activities. With an unwavering dedication to innovation, this company is making strides to reshape the industry landscape, offering businesses a competitive edge in the global market.I. Smelting Equipment's Technological Breakthrough:The newly developed smelting equipment, (remove brand name), represents a technological breakthrough for the industry. It incorporates advanced features and functionalities that streamline the smelting process, offering significant advantages to companies looking to optimize their operations. With an emphasis on efficiency and sustainability, this cutting-edge equipment is built to minimize energy consumption, reduce waste, and enhance the overall quality of the end product.The equipment's intelligent monitoring system ensures accurate temperature control, resulting in improved metal purity and reduced material losses. Additionally, the incorporation of automation technology not only minimizes the risk of human error but also enables the equipment to operate continuously for extended periods, significantly boosting production capacity.II. Enhanced Safety Measures:In line with industry demands for improved safety standards, the smelting equipment integrates comprehensive safety measures to protect both operators and the environment. The introduction of advanced sensors and alarms monitors critical parameters such as temperature, pressure, and gas concentration, promptly alerting operators to any potential risks or deviations. This proactive approach ensures a safer working environment and minimizes the likelihood of accidents.Furthermore, the equipment is designed with a state-of-the-art waste gas treatment system, effectively reducing emissions and adhering to stringent environmental regulations. By minimizing environmental impact, companies utilizing this advanced smelting equipment demonstrate their commitment towards sustainable manufacturing practices.III. Improved Cost-efficiency and Resource Optimization:With the new smelting equipment, companies can expect significant cost savings and resource optimization. The integration of precision control mechanisms maximizes the extraction of valuable metals from raw materials, reducing the amount of waste generated. This enhanced efficiency not only reduces material costs but also contributes to a more sustainable use of available resources.Moreover, the equipment's intelligent energy management system optimizes power consumption by regulating energy output during peak and low demand periods. This results in reduced energy bills for companies and a smaller overall carbon footprint, aligning with contemporary goals of environmental stewardship.IV. Market Competitiveness and Global Reach:With the adoption of this advanced smelting equipment, companies gain a competitive edge in the global market. The increased efficiency and improved product quality achieved through the equipment's cutting-edge technology allow businesses to meet customer demands more effectively and respond to market fluctuations with greater agility.By embracing sustainability and incorporating state-of-the-art equipment into their manufacturing processes, companies utilizing this smelting equipment can market their products as environmentally responsible and gain a competitive advantage in increasingly eco-conscious markets.V. Company's Commitment to Innovation:The development and launch of this breakthrough smelting equipment signify the company's commitment to ongoing innovation and industry leadership. With a dedicated research and development team, the company continues to leverage the latest technology to enhance its offerings, meeting the evolving needs of the industrial sector.As a leading provider of smelting equipment, the company remains focused on providing comprehensive solutions to its customers and contributing to the advancement of the manufacturing industry as a whole. Their dedication to innovation ensures that businesses can achieve improved operational efficiencies, environmental sustainability, and increased profitability.Conclusion:The unveiling of advanced smelting equipment by (remove brand name) marks a revolutionary turning point for manufacturing companies engaged in metal refining. With enhanced efficiency, safety, and sustainability, this cutting-edge equipment empowers businesses to optimize their smelting processes, reduce costs, and gain a competitive edge in the global market. As the company continues to spearhead innovation, the future of the smelting industry looks increasingly promising, ushering in a new era of heightened performance and environmental responsibility.

Leading Manufacturers of Electric Furnace-Melted Copper Offering High-Quality Products

Electric Furnace Melting Copper Manufacturers, in line with their commitment to delivering top-quality products to their valued customers, are revolutionizing the copper industry with their cutting-edge technology and unmatched expertise. With a strong emphasis on innovation and customer satisfaction, this leading manufacturer is constantly pushing the boundaries of what is possible in the field of electric furnace melting.Electric furnace melting has gained significant popularity in recent years due to its efficiency and environmentally friendly nature. It eliminates the need for traditional fuel sources, such as coal or oil, and significantly reduces greenhouse gas emissions. This method of copper production is not only more sustainable but also allows for a more precise control of the melting process, resulting in a superior quality product.At the forefront of this industry, Electric Furnace Melting Copper Manufacturers have made substantial investments in research and development, allowing them to develop advanced electric furnaces that guarantee optimal performance and reliability. These state-of-the-art furnaces are equipped with advanced features, including temperature control systems, automatic feeding mechanisms, and precise metal pouring systems.Thanks to their continuous innovation, Electric Furnace Melting Copper Manufacturers have earned a well-deserved reputation for producing copper with exceptional purity and consistency. Their electric furnaces are capable of melting various forms of copper, including scraps, wires, and ingots, ensuring maximum material utilization and minimal waste generation.To ensure the highest quality standards, the company has implemented a rigorous quality control system at every stage of the production process. From the sourcing of raw materials to the melting and casting processes, every step is closely monitored to guarantee the production of superior-grade copper. This commitment to quality has earned Electric Furnace Melting Copper Manufacturers the trust and loyalty of numerous clients across various industries, including electrical, automotive, and construction.Moreover, Electric Furnace Melting Copper Manufacturers understand that different customers have unique requirements. Therefore, they offer customized solutions to meet the specific demands of their clientele. Their team of highly skilled engineers works closely with clients to design and manufacture electric furnaces tailored to their individual needs, ensuring optimal performance and maximum productivity.In addition to their exceptional products, Electric Furnace Melting Copper Manufacturers also excel in customer service. Their dedicated and knowledgeable team is always ready to assist clients with any queries or concerns, providing prompt and efficient support. With a strong focus on building long-term relationships with their customers, the company strives to exceed expectations and deliver unparalleled satisfaction.Looking towards the future, Electric Furnace Melting Copper Manufacturers continue to invest in the advancement of electric furnace technology. Their team of experienced researchers and engineers are constantly exploring new possibilities and refining existing processes to further enhance the efficiency and effectiveness of their electric furnaces.In conclusion, Electric Furnace Melting Copper Manufacturers are revolutionizing the copper industry with their cutting-edge technology and commitment to excellence. By harnessing the power of electric furnace melting, they are able to produce high-quality copper while minimizing environmental impact. With their customer-centric approach and dedication to continuous improvement, Electric Furnace Melting Copper Manufacturers are setting new standards for the industry and cementing their position as leaders in the field.

Top Zinc Melting Furnace Suppliers Discussed in Latest News

In recent years, the demand for zinc melting furnaces has been steadily increasing due to the growth of various industries such as automotive, construction, and electronics. As a result, the market has witnessed the emergence of several prominent zinc melting furnace suppliers. While it's crucial to find the best suppliers in the market, in this article, we will focus on the essential features of top zinc melting furnace suppliers without mentioning any brand names.These suppliers are known for their commitment to quality, customer satisfaction, and innovative technologies. They prioritize providing reliable and efficient zinc melting furnaces to meet the diverse needs of their clients. By understanding the unique requirements of industries such as zinc smelting, die casting, and galvanizing, they are able to deliver cutting-edge furnace solutions.One of the key factors contributing to the success of these top suppliers is their emphasis on research and development (R&D). They invest heavily in R&D to continuously improve their products' performance, energy efficiency, and environmental friendliness. These suppliers understand the importance of staying ahead of the curve and providing customers with the latest advancements in technology.Furthermore, these market leaders have an extensive network of sales and support teams, ensuring that their customers receive excellent service throughout the buying and installation process. They have well-trained professionals who can guide clients in choosing the right furnace based on their specific requirements, budget, and production scale. These suppliers also offer after-sales support, maintenance services, and spare parts to guarantee the smooth running of the furnace.To ascertain that their products meet the highest quality standards, these top suppliers adhere to stringent quality control measures. They have state-of-the-art manufacturing facilities equipped with advanced testing equipment to ensure the reliability and durability of their furnaces. Moreover, they source only the finest materials and components from reputable suppliers to guarantee the longevity and performance of their products.In addition to their commitment to quality, these suppliers actively prioritize environmental sustainability. They incorporate energy-saving technologies and employ eco-friendly materials to reduce the carbon footprint of their zinc melting furnaces. By adopting efficient combustion techniques and recycling systems, they contribute to the reduction of greenhouse gas emissions, making them eco-friendly choices for industrial applications.To cater to the diverse needs of customers, these suppliers offer a wide range of zinc melting furnaces with varying capacities and features. Whether clients require small and compact furnaces for laboratory purposes or large-scale furnaces for industrial production, these suppliers have solutions to meet different demands. They ensure that their furnaces are not only efficient and reliable but also flexible enough to adapt to different production requirements.Furthermore, these suppliers continuously strive to improve their pricing strategies, ensuring that their products are competitively priced in the market. They offer transparent pricing structures and work closely with customers to provide cost-effective solutions without compromising on quality. By maintaining a balance between affordability and performance, these suppliers attract a wide customer base.In conclusion, the zinc melting furnace market is witnessing the rise of top suppliers who prioritize excellence in quality, customer satisfaction, and innovation. These suppliers invest in R&D, have extensive sales and support networks, emphasize strict quality control measures, promote environmental sustainability, and offer a diverse range of furnaces. By understanding the specific needs of industries and continuously improving their products, these suppliers have become reliable and trustworthy partners for clients in need of zinc melting furnaces.

Best Supplier for Induction Furnace Frequencies

Induction furnaces have revolutionized the world of metallurgy and manufacturing, providing a highly efficient and cost-effective alternative to traditional methods of melting and pouring metal. One crucial component of these furnaces is the frequency converter, which controls the power sent to the induction coil, and subsequently, the melting process. In today's market, finding the best induction furnace frequency supplier is essential for success, and one company stands out from the rest.This particular supplier is a leader in the field of frequency converters, providing world-class products to numerous industries worldwide. With over 30 years of experience, this company has developed an extensive portfolio of solutions, ranging from low to high-power frequency converters, for all types of induction heating applications, including melting, welding, brazing, annealing, and more.Moreover, the company's products come equipped with advanced features and technologies, designed to optimize the melting process while ensuring safety, reliability, and efficiency. Their team of engineers works closely with customers to understand their needs and provide customized solutions that will maximize productivity and minimize downtime.One of the most notable features of this supplier's frequency converters is their ability to adjust to different operating frequencies and power levels. This flexibility allows for easy adaptation to varying melting processes and assists in maximizing energy efficiency. Additionally, their products come with active power factor correction and harmonic suppression, which helps to reduce energy consumption while minimizing electromagnetic interference.For customers operating in harsh environments, the supplier's frequency converters feature robust and rugged designs that ensure reliability and durability. The converters can withstand harsh environmental factors such as dust, high temperatures, humidity, and vibration, making them suitable for a wide range of applications across different industries.The company also offers a range of value-added services, including installation, after-sales support, and a comprehensive maintenance program. The company's commitment to providing excellent customer service extends through every aspect of their business and is reflected in their long-standing reputation for quality and reliability.Furthermore, the supplier prides itself on its commitment to sustainability, continuously working to create products that are both environmentally friendly and energy-efficient. Their advanced technological features help their customers to reduce their carbon footprint and lower energy costs, leading to a significant positive impact on the environment.In summary, finding the best induction furnace frequency supplier is crucial for companies operating in the metallurgy and manufacturing industry. The supplier mentioned above offers a comprehensive range of solutions designed to optimize the melting process, reduce energy costs, and provide unparalleled customer service. With over 30 years of experience and a commitment to sustainability, this supplier is the perfect choice for any business looking to maximize efficiency and productivity.

Top Suppliers of High-Quality Copper Scrap Melting Furnaces for Various Industries

Title: Leading Copper Scrap Melting Furnace Suppliers Revolutionize Smelting IndustryIntroductionThe smelting industry forms a crucial link in the global manufacturing supply chain, supporting numerous sectors such as automotive, construction, electrical, and electronics. Within this industry, copper scrap melting furnaces play a pivotal role in the efficient recycling and refining of copper materials, thereby reducing environmental impact and conserving valuable resources. Amidst growing demand for sustainable and technologically advanced solutions, a host of influential suppliers have emerged as leaders in the market. In this article, we will explore the innovative offerings of several prominent copper scrap melting furnace suppliers and their contributions to the industry's development.Supplier 1: (Name removed)Renowned for its cutting-edge technology and extensive industry expertise, Supplier 1 has indubitably made its mark in the global copper scrap melting furnace market. Equipped with a diverse portfolio, the company delivers a range of high-quality furnaces tailored to the varying needs of its clientele. These furnaces exhibit remarkable energy efficiency, thus reducing electricity costs and minimizing carbon emissions. Supplier 1's commitment to research and development continually drives groundbreaking advancements, ensuring its customers benefit from the latest innovations in the field.Supplier 1's furnaces are known for their exceptional heat transfer capabilities, enabling quick and precise melting of copper scrap. This not only improves productivity but also results in reduced material wastage. The company's dedication to supporting eco-conscious practices is evident through its use of state-of-the-art pollution control mechanisms, ensuring compliance with stringent environmental regulations. By offering highly efficient exhaust gas purification systems, Supplier 1 contributes to a sustainable smelting process while minimizing the impact on local communities.Supplier 2: (Name removed)Another industry leader, Supplier 2, has been at the forefront of providing reliable and superior copper melting furnace solutions to its global clientele. With a proven track record of delivering high-performance products, Supplier 2 has gained a reputation for its commitment to quality, efficiency, and customer satisfaction. Their furnaces are meticulously designed to facilitate easy operation and maintenance, ensuring minimal downtime for businesses.Supplier 2 embraces advanced technology to optimize the melting process, resulting in higher productivity and enhanced flexibility for users. The company's dedication to environmental stewardship is reflected in its utilization of cutting-edge filtration systems that effectively remove harmful particulates, minimizing air pollution. Furthermore, Supplier 2's continuous focus on energy efficiency allows customers to reduce energy consumption, benefiting both their bottom line and the planet.Supplier 3: (Name removed)Supplier 3 is an eminent supplier in the copper scrap melting furnace market, offering a broad range of technologically advanced furnaces that cater to the diverse needs of its global clientele. The company’s commitment to sustainability is evident in its furnaces, which are designed to minimize energy consumption while maximizing operational efficiency. Supplier 3's revolutionary heat control technology ensures precise temperature management during the melting process, allowing for greater consistency in the final product.Moreover, Supplier 3 emphasizes safety as a paramount concern, integrating robust safety features into its furnaces for the protection of workers. With comprehensive control systems and real-time monitoring capabilities, customers can effectively manage and optimize their production processes. By prioritizing innovation and reliability, Supplier 3 has established itself as a trusted partner in the copper smelting industry.ConclusionIn an era of rapid industrialization and growing environmental concerns, the contributions made by leading copper scrap melting furnace suppliers cannot be overstated. Through continuous innovation and commitment to sustainability, these companies are transforming the smelting industry, paving the way for a greener and more efficient future. By leveraging advanced technologies and stringent quality control measures, these suppliers ensure that their customers enjoy enhanced productivity, reduced operational costs, and a reduced environmental footprint. As the demand for copper continues to rise, these influential leaders will undoubtedly play a critical role in shaping a more sustainable and prosperous industry.

Top Electric Melting Furnace Suppliers You Should Know About

Title: Leading Electric Melting Furnace Supplier Revolutionizes the Industry through InnovationIntroduction:Electric melting furnaces have revolutionized various industries by providing efficient and environmentally-friendly solutions for melting metals and alloys. One company that has consistently stood out among its competitors is a renowned industry leader (brand name). With its extensive experience and dedication to innovation, this leading electric melting furnace supplier has set new standards for excellence in the industry.Body:1. Company Overview:(About the Company):For over (number of years) years, (brand name) has been at the forefront of the electric melting furnace industry, pioneering the development of cutting-edge technology. The company has built a reputation for its commitment to quality, reliability, and customer satisfaction.(Product Range):(brand name) offers a diverse range of electric melting furnaces suitable for a variety of industrial applications. From small-scale foundries to large-scale industrial settings, the company provides customized solutions to meet the specific requirements of each customer.(Eco-friendly Approach):The company is committed to reducing its environmental impact by incorporating advanced eco-friendly technologies in its production processes. (brand name)'s electric melting furnaces are designed to minimize energy consumption while maintaining optimal performance, thus significantly reducing carbon emissions.2. Innovative Technology:(a) Advanced Heating Elements:(brand name) employs innovative heating elements that ensure precise temperature control, resulting in efficient and uniform melting. These state-of-the-art elements provide rapid heating and superior heat insulation, optimizing energy efficiency and reducing operational costs.(b) Sensor Technology:The use of advanced sensors enables (brand name) to provide real-time monitoring and control of the melting process. This technology ensures consistent and reliable performance, minimizes human error, and improves overall productivity.(c) Automation and IoT Integration:Embracing the era of automation and digitalization, (brand name) integrates its electric melting furnaces with the Internet of Things (IoT). This allows for remote monitoring and control, predictive maintenance, and data analysis, enabling customers to optimize operations and make informed decisions.3. Unparalleled Customer Support:(a) Customization:Understanding that each client has unique requirements, (brand name) offers tailor-made solutions to meet their specific needs. The company's team of experts works closely with customers to design and manufacture electric melting furnaces that align with their individual applications and production goals.(b) Technical Assistance:(brand name) provides comprehensive technical support to its customers, ensuring seamless integration and operation of their electric melting furnaces. With a dedicated team of experienced engineers and technicians, the company offers prompt assistance, maintenance, and troubleshooting services to ensure optimal performance and customer satisfaction.(c) Training and Knowledge Sharing:Recognizing the importance of expertise and training, (brand name) conducts training programs to enhance the knowledge and skills of its customers. These programs aim to equip users with the necessary understanding of the electric melting furnaces and their operational practices, maximizing efficiency and safety.Conclusion:Through its relentless commitment to innovation, customer satisfaction, and environmental responsibility, (brand name) has established itself as the go-to supplier of electric melting furnaces. With its cutting-edge technology, customization options, and unparalleled customer support, the company continues to redefine the industry landscape, setting new standards for excellence. As demand for efficient and sustainable melting solutions grows, (brand name) remains dedicated to providing innovative solutions that meet the evolving needs of its customers and contribute to a greener future.

The Importance of Selecting a High-Quality Furnace Manufacturer for Efficient Metal Smelting

Title: Revolutionary Industrial Furnace Manufacturer Introduces Cutting-Edge Technology for Enhanced Metal Melting Processes Introduction: In the ever-evolving landscape of industrial manufacturing, the need for efficient and eco-friendly metal melting processes has become paramount. Enter the pioneering furnace manufacturer, renowned for its ground-breaking innovations and unwavering commitment to quality and customer satisfaction. This revolutionary company, distinguished for its unmatched research and development capabilities, is set to revolutionize metal melting through its state-of-the-art technology.Revolutionizing Metal Melting Processes:With a rich history of exceeding industry expectations, this visionary furnace manufacturer has left an indelible mark on the global manufacturing landscape. By leveraging a deep understanding of user requirements and utilizing cutting-edge technology, they have successfully developed an array of furnaces with unrivaled capabilities.One of the most prominent achievements of this manufacturer is the development of their advanced induction heating technology. This groundbreaking technology harnesses the power of electromagnetic induction to efficiently melt a wide range of metals. With remarkable precision, these induction furnaces can melt and heat metals within seconds, significantly reducing production time and optimizing throughput. Moreover, this energy-efficient technology ensures minimal waste, making it an environmentally friendly solution.Committed to customer satisfaction, this manufacturer strives to offer versatility in their product lineup. Understanding the diversity of metal melting requirements across industries, they have meticulously designed a range of furnaces catering to different needs. From small-scale melting furnaces for laboratory purposes to large-scale industrial furnaces for mass production, this manufacturer offers tailored solutions to meet specific demands.Moreover, this furnace manufacturer's commitment to innovation is evident in their incorporation of the latest automation technologies into their products. Advanced features such as temperature control systems, automatic feeding mechanisms, and real-time monitoring capabilities enhance both productivity and safety. Such technological advancements streamline operations by minimizing human intervention and ensuring precise control over the metal melting process.The manufacturer's unwavering dedication to quality and reliability is exemplified by their stringent quality control measures. Every furnace undergoes rigorous testing protocols, ensuring that only products of the highest standards reach the market. By conforming to international quality certifications, this manufacturer assures their customers of the durability and longevity of their products.Furthermore, this forward-thinking furnace manufacturer recognizes the importance of comprehensive after-sales support. Their team of skilled technicians and engineers offers prompt assistance for installation, maintenance, and troubleshooting. This commitment to customer care ensures that the benefits of their cutting-edge technology are fully realized by their clients, ultimately driving productive and efficient metal melting processes.Expanding Global Footprint:This esteemed furnace manufacturer's relentless pursuit of excellence has propelled them to establish a robust global presence. With an extensive distribution network and strategic partnerships, they have successfully catered to the evolving demands of industries worldwide. By offering not just superior products, but also impeccable customer service, this manufacturer has consistently outperformed competitors, securing a trusted position in the market.Conclusion:In a fiercely competitive industrial landscape, distinguished by constant technological advancements, this revolutionary furnace manufacturer stands tall as a leading provider of innovative metal melting solutions. Guided by their unwavering commitment to quality, customer satisfaction, and environmental responsibility, they continue to redefine industry standards in terms of efficiency, reliability, and precision. With their cutting-edge technology and comprehensive after-sales support, industries across the globe can look forward to enhanced metal melting processes and streamlined production, powered by the products of this visionary manufacturer.