Lead Melting Furnace Factories in China: An Overview of Electric Models

By:Admin

The company's success can be attributed to several factors, one of which is their unwavering dedication to producing high-quality products. Every lead melting furnace that comes out of their factories is meticulously crafted by a team of skilled technicians and engineers. The company also incorporates the latest technological advancements in their manufacturing processes, ensuring that their products are not only of superior quality but also highly efficient and reliable.

Furthermore, the company places a strong emphasis on research and development, constantly seeking new ways to improve their products and meet the evolving needs of their customers. This commitment to innovation has enabled them to stay ahead of the competition and remain a top choice for businesses in need of lead melting furnaces.

In addition to their impressive manufacturing capabilities, China Electric Lead Melting Furnace Factories also prides itself on its exceptional customer service. The company understands the importance of building strong relationships with their clients, and as such, they go above and beyond to ensure that every customer is satisfied with their purchase. From the initial inquiry to after-sales support, the company's team is highly responsive and always willing to assist in any way they can.

The company's dedication to quality and customer satisfaction has not gone unnoticed, as they have received accolades and recognition for their outstanding work. Their lead melting furnaces are highly sought after by businesses in various industries, including metal processing, recycling, and manufacturing. With a proven track record of delivering top-notch products and services, China Electric Lead Melting Furnace Factories has solidified its position as a reputable and reliable company in the industry.

Looking ahead, the company is not content with resting on its laurels. They are continuously exploring new opportunities for growth and expansion, both domestically and internationally. With an eye on global markets, China Electric Lead Melting Furnace Factories is eager to introduce their exceptional products to a wider audience and make an even greater impact on the industry.

In the midst of their ongoing success, the company remains committed to upholding their core values of integrity, excellence, and innovation. They understand that their reputation is only as strong as their last customer interaction, and as such, they continue to hold themselves to the highest standards of professionalism and quality.

In conclusion, China Electric Lead Melting Furnace Factories has set the bar high for the manufacturing and supply of electric lead melting furnaces. Their unwavering commitment to excellence, combined with their dedication to customer satisfaction, has earned them a well-deserved reputation as a leader in the industry. As they continue to grow and expand their reach, there is no doubt that the company will maintain its position at the forefront of innovation and quality in the field of lead melting furnaces.

Company News & Blog

Discover an Efficient Solution for Your Furnace Needs

Title: Next-Generation Furnace Showcases Groundbreaking Innovations in Casting IndustryIntroduction:In a bid to revolutionize the casting industry, a renowned furnace manufacturer has unveiled its latest product, the groundbreaking Cast Master Furnace. This state-of-the-art furnace is set to redefine the standards of casting technology with its advanced features and efficient performance. The new Cast Master Furnace signifies a significant leap forward, promising unparalleled precision, productivity, and sustainability for casting professionals worldwide.1. Advanced Technology Enhancing Precision:The Cast Master Furnace integrates cutting-edge technology to provide a higher level of precision in the casting process. Incorporating advanced sensors and sophisticated software, the furnace ensures accurate temperature control, preventing overheating or underheating of the metal alloys. This breakthrough technology guarantees exceptional product quality and reduces wastage, enabling casting professionals to achieve the desired results consistently.Furthermore, the furnace's innovative design enables precise monitoring of various parameters such as gas flow, pressure, and air ratios, ensuring optimized combustion. This not only enhances energy efficiency but also minimizes environmental impact, making the Cast Master Furnace a sustainable choice for casting operations.2. Increased Productivity with Smart Features:Recognizing the importance of productivity in the casting industry, the Cast Master Furnace offers a host of smart features that streamline the casting process and reduce downtime. The inclusion of remote monitoring capabilities allows operators to track the furnace's performance, identify potential issues, and make real-time adjustments from a centralized control panel. This remote operation feature enhances efficiency and reduces the need for manual intervention, resulting in improved productivity levels.In addition to remote monitoring, the Cast Master Furnace incorporates an intelligent scheduling system that optimizes the casting cycle based on various factors like alloy composition, mold complexity, and cooling requirements. By automating the scheduling process, the furnace allows for efficient use of resources, thereby maximizing productivity and reducing production costs.3. Sustainability and Energy Efficiency:The Cast Master Furnace is designed to promote sustainable practices and reduce energy consumption in the casting industry. Utilizing state-of-the-art insulation materials, the furnace minimizes heat loss, improving energy efficiency while ensuring a safer working environment.Moreover, the furnace employs a multi-stage filtration system to capture and treat harmful emissions, significantly reducing pollutants released into the atmosphere. This commitment to environmental responsibility aligns with global efforts to mitigate the carbon footprint of industrial processes, making the Cast Master Furnace an environmentally-conscious choice.4. Collaborative Approach for Industry Advancement:The introduction of the Cast Master Furnace demonstrates the manufacturer's commitment to fostering collaboration within the casting industry. The company has actively engaged with casting professionals, incorporating their valuable feedback and insights during the development phase. By combining extensive industry experience with cutting-edge technology, the manufacturer has addressed the specific challenges faced by casting professionals, resulting in an innovative furnace tailored to their unique requirements.Furthermore, the company offers comprehensive technical support, including training programs and prompt assistance from a team of experts. By nurturing a collaborative environment, the manufacturer strives to empower casting professionals with the necessary knowledge and skills to optimize their casting operations effectively.Conclusion:As the casting industry moves towards a more technologically advanced era, the Cast Master Furnace leads the way with its groundbreaking features, exceptional precision, and commitment to sustainability. This advanced furnace promises to revolutionize the casting process, enabling professionals to achieve higher levels of accuracy, productivity, and energy efficiency. With its innovative design and comprehensive support system, the Cast Master Furnace is set to become the choice of casting professionals worldwide, positioning the industry for a brighter and more sustainable future.

Top Electric Metal Melting Furnace for Efficient Metal Melting Operations

The electric metal melting furnace is an essential piece of equipment for many industries that rely on the melting and casting of metal. Whether it's for creating intricate jewelry pieces, manufacturing industrial parts, or crafting custom-designed metal sculptures, the electric metal melting furnace plays a crucial role in the production process.One of the leading companies in the field of electric metal melting furnaces is {Company Name}. With a strong focus on innovation and advanced technology, {Company Name} has established itself as a reliable and trusted provider of high-quality electric metal melting furnaces.{Company Name} offers a wide range of electric metal melting furnaces that are designed to meet the diverse needs of their customers. Whether it's a small, compact furnace for a jewelry workshop or a larger, more powerful furnace for an industrial facility, {Company Name} has the expertise and experience to provide the right solution.One of the key features of {Company Name}'s electric metal melting furnaces is their efficiency and reliability. The furnaces are built to withstand high temperatures and long hours of operation, ensuring consistent and uniform melting of the metal. This not only improves the quality of the final product but also enhances the overall productivity of the manufacturing process.In addition to their durability, {Company Name}'s electric metal melting furnaces are also designed with safety in mind. The furnaces are equipped with advanced safety features to prevent accidents and ensure the well-being of the operators. This attention to safety further demonstrates {Company Name}'s commitment to providing top-quality products that prioritize both performance and the welfare of their customers.Furthermore, {Company Name} takes pride in their commitment to environmental sustainability. Their electric metal melting furnaces are designed to minimize energy consumption and reduce carbon emissions, making them an eco-friendly choice for businesses looking to minimize their environmental impact. This aligns with {Company Name}'s overarching goal of promoting sustainable manufacturing practices and contributing to a greener, more eco-conscious industry.The electric metal melting furnaces offered by {Company Name} are also known for their user-friendly design and ease of operation. With intuitive controls and clear instructions, operators can easily manage the melting process with confidence and precision. This user-focused approach reflects {Company Name}'s dedication to providing a seamless and efficient experience for their customers.In addition to their exceptional products, {Company Name} also provides comprehensive customer support services to ensure that their clients receive ongoing assistance and guidance. From installation and training to maintenance and troubleshooting, {Company Name} stands by their customers every step of the way, guaranteeing a positive and successful experience with their electric metal melting furnaces.The success and reputation of {Company Name} in the industry can be attributed to their unwavering dedication to excellence and their relentless pursuit of innovation. By continuously pushing the boundaries of technology and manufacturing, {Company Name} has positioned itself as a leading provider of electric metal melting furnaces, setting the standard for reliability, performance, and customer satisfaction.With their continued commitment to quality and customer-centric approach, {Company Name} is poised to remain a dominant force in the market, driving the advancement of electric metal melting furnace technology and helping businesses around the world achieve their production goals with confidence and ease.

High-Quality Copper Crucible Furnace for Efficient Melting

The Copper Crucible Furnace, developed and manufactured by a leading industrial technology company, is making waves in the metallurgy industry with its advanced and innovative technology. This state-of-the-art furnace is redefining the smelting process, offering a more efficient and cost-effective solution for copper production.The Copper Crucible Furnace is designed to handle the high-temperature requirements of copper smelting, providing a reliable and sustainable solution for the industry. The furnace is built with a high-quality refractory material to withstand extreme temperatures, ensuring optimal performance and durability.One of the key features of the Copper Crucible Furnace is its advanced control system, which allows for precise temperature and process control. This ensures consistent and high-quality copper production, while also reducing energy consumption and operational costs.Additionally, the furnace is equipped with a sophisticated waste heat recovery system, which helps to minimize heat loss and improve overall energy efficiency. This not only reduces the environmental impact of the smelting process but also contributes to significant cost savings for copper producers.Another standout feature of the Copper Crucible Furnace is its modular design, which allows for easy installation and maintenance. This flexibility makes it an ideal choice for both new smelting facilities and retrofitting existing ones, offering a seamless and hassle-free integration into any production setup.In addition to its technical capabilities, the Copper Crucible Furnace has also been designed with a strong focus on safety and environmental sustainability. The furnace is equipped with advanced emissions control technology, ensuring compliance with stringent environmental regulations and minimizing the impact of copper production on the surrounding ecosystem.Furthermore, the company behind the Copper Crucible Furnace is committed to providing comprehensive support and services to its customers. From initial consultation and custom design to installation, training, and ongoing maintenance, the company offers a complete package to ensure the success and efficiency of its furnace in any copper smelting operation.The Copper Crucible Furnace has already garnered significant attention and praise within the industry, with several successful installations and positive feedback from clients. Its cutting-edge technology and proven performance have set a new standard for copper smelting, positioning it as a game-changer in the metallurgy sector.In conclusion, the Copper Crucible Furnace, developed and manufactured by a leading industrial technology company, is revolutionizing the copper smelting process with its advanced and innovative design. With its exceptional performance, energy efficiency, and environmental sustainability, this furnace is poised to reshape the future of copper production, offering a reliable and cost-effective solution for the industry. Its modular design, advanced control system, and comprehensive support services make it a top choice for any copper smelting operation, setting a new benchmark for excellence in the metallurgy sector.Overall, the Copper Crucible Furnace is not just a furnace, it's a game-changer in the copper production industry.

High-Efficiency Aluminum Can Melting Furnace for Industrial Use

Aluminum Can Melting Furnace Revolutionizes Recycling ProcessIn a world increasingly focused on sustainability, the need for efficient and effective recycling processes has never been greater. This need has led to the development of innovative technologies, such as the Aluminum Can Melting Furnace, a groundbreaking new system that promises to revolutionize the recycling of aluminum cans.The Aluminum Can Melting Furnace, developed by a leading industrial equipment manufacturer in the industry, is an advanced melting system designed to address the challenges of aluminum can recycling. It is specially engineered to melt aluminum cans at high temperatures, allowing for the recovery of aluminum in its purest form. This innovative technology offers a sustainable solution for the recycling industry by optimizing the use of resources and minimizing waste.With a focus on sustainability and environmental responsibility, the company behind the Aluminum Can Melting Furnace has a strong commitment to developing advanced technologies that contribute to a circular economy. Their expertise in industrial equipment design and manufacturing positions them as a leader in providing innovative solutions for the recycling industry.The company's dedication to sustainability is reflected in their state-of-the-art manufacturing facilities and their investment in research and development of advanced recycling technologies. The Aluminum Can Melting Furnace is the latest addition to their portfolio of cutting-edge equipment, showcasing their commitment to addressing the pressing environmental challenges facing the world today.The Aluminum Can Melting Furnace is set to transform the aluminum can recycling process, offering a more efficient and sustainable solution for melting and recovering aluminum from cans. Its advanced design and high-temperature capabilities make it a game-changer in the recycling industry, providing a cost-effective and environmentally friendly method for processing aluminum cans.With the Aluminum Can Melting Furnace, the company aims to support the transition towards a more sustainable and circular economy by offering a technology that enables the recycling of aluminum cans in a more efficient and environmentally friendly manner. This aligns with the company's vision of becoming a global leader in providing sustainable solutions for the recycling industry.The Aluminum Can Melting Furnace is expected to have a significant impact on the recycling industry, as it presents a viable solution for meeting the growing demand for recycled aluminum. By enabling the recovery of aluminum in its purest form, the technology offers a more sustainable alternative to traditional aluminum can recycling methods, reducing the environmental impact and promoting a more circular approach to resource management.Moreover, the Aluminum Can Melting Furnace is designed to be highly efficient, reducing energy consumption and operating costs. This makes it a compelling choice for recyclers looking to improve their operational efficiency and minimize their environmental footprint. With the ability to process a large volume of aluminum cans in a relatively short period, the technology offers a scalable solution for recyclers looking to increase their aluminum recycling capacity.In conclusion, the Aluminum Can Melting Furnace represents a significant advancement in the recycling industry, offering a more sustainable and efficient solution for processing aluminum cans. With its advanced design and high-temperature capabilities, the technology promises to revolutionize the way aluminum cans are recycled, contributing to a more sustainable and circular economy. As the company continues to lead the way in developing innovative recycling technologies, the Aluminum Can Melting Furnace stands as a testament to their commitment to sustainability and environmental responsibility.

Guide to Induction Melting Metal for Efficient Metal Processing

Title: Induction Melting Technology Revolutionizes Metal Processing - A Game-Changer in Manufacturing IndustriesIntroduction (100 words):In the realm of metal processing, innovative technologies have consistently played a vital role in driving progress and efficiency. One such groundbreaking invention is induction melting technology - an advanced, high-performance method designed to enhance metal melting and refining processes. Developed and perfected by {company name}, this cutting-edge technique is revolutionizing the manufacturing industry. This news article will delve into the intricacies of induction melting, its various applications, and the extensive benefits it offers to businesses across different sectors.Section 1: The Power of Induction Melting for Metal Processing (200 words)Since its introduction, induction melting technology has transformed the way metals are melted and processed. Utilizing electromagnetic induction, this technique employs an alternating current to generate a magnetic field that induces eddy currents within the metal product being melted. These eddy currents, in turn, produce heat due to resistance, leading to the melting of the metal.One of the primary advantages of induction melting is its ability to achieve high melting rates. Compared to traditional melting methods, induction melting proves to be significantly faster and more energy-efficient. This technology also ensures uniform heating, preventing hot spots or inconsistencies in the metal surface, resulting in a higher-quality end product.Section 2: Applications of Induction Melting (250 words)The versatility of induction melting makes it applicable to a broad range of industries. From small-scale foundries and metalworking companies to larger manufacturing plants, this technology has become indispensable across many sectors.In the automotive industry, induction melting has revolutionized the production of critical engine components such as pistons, cylinders, and crankshafts. Through high-precision melting and alloying, this advanced method enhances the durability, strength, and performance of these vital automotive parts.Additionally, the aerospace industry benefits greatly from induction melting technology. From constructing turbine blades to manufacturing aircraft parts, the rapid heating and precise temperature control offered by this technique ensures the production of lightweight, high-strength, and heat-resistant components.Other sectors, such as jewelry manufacturing, electrical equipment manufacturing, and metal recycling, have all turned to induction melting for its accuracy, speed, and cost-efficiency. The process is easily customizable to cater to specific melting requirements, making it an ideal choice for various metallurgical applications.Section 3: {Company Name} - A Pioneer in Induction Melting Technology (200 words){Company Name} has established itself as a frontrunner in the field of induction melting, relentlessly pushing boundaries and setting new standards for metal processing. With years of research and development, the company has perfected their advanced induction melting equipment and machines - removing thermal inefficiencies and enhancing energy utilization.The company's range of induction melting systems offers flexibility, efficiency, and unmatched performance. These systems are designed to melt different types of metals, including steel, iron, aluminum, and precious metals, enabling businesses to harness the full potential of induction melting technology.Moreover, {Company Name} provides comprehensive training and support to ensure seamless integration of the technology into existing manufacturing processes. They have also introduced user-friendly interfaces and automated features to simplify operation and maximize productivity.Conclusion (150 words):Induction melting technology has truly revolutionized metal processing, providing an unparalleled solution for businesses seeking enhanced efficiency and quality in their manufacturing processes. With its ability to achieve uniform heating, precise control, and remarkable energy efficiency, this technology is instrumental in shaping the future of various industries. {Company Name}'s expertise and innovation continue to drive the advancements and adoption of this groundbreaking technology, cementing its role as a pioneer in the field.By harnessing the power of induction melting technology, businesses can optimize their operations, reduce costs, and deliver superior products to meet the ever-growing demands of the modern market. As the manufacturing industry continues to evolve, induction melting stands as a testament to the transformative capabilities of technology in shaping progress and growth.

Lead Melting Furnace Factories in China: An Overview of Electric Models

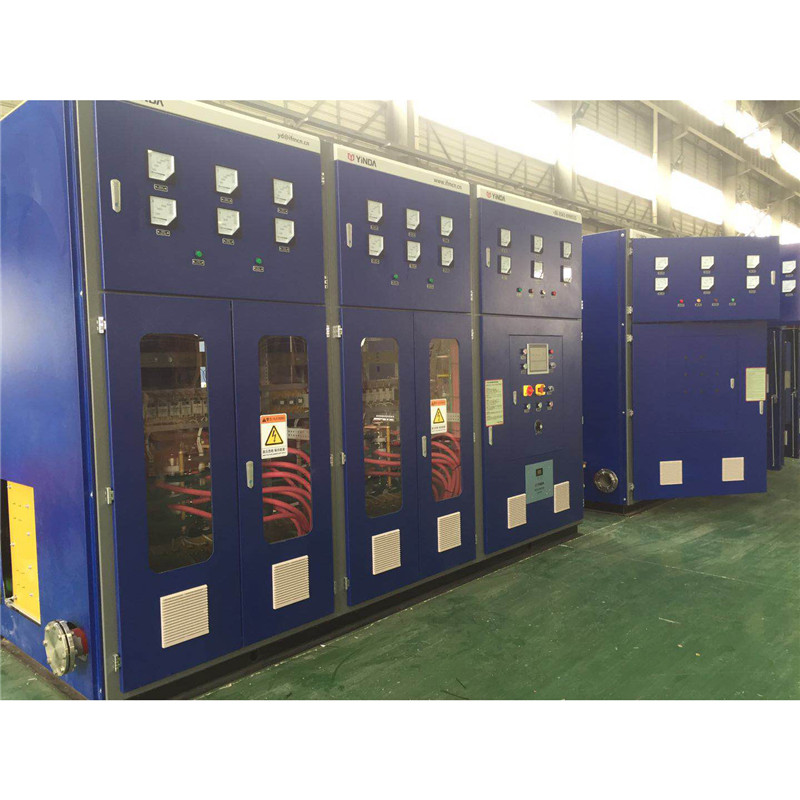

China Electric Lead Melting Furnace Factories has been making a mark in the industry with its impeccable quality and commitment to excellence. With a reputation that precedes them, the company has been at the forefront of innovation in the field of lead melting furnaces. Established in the early 2000s, the company has steadily grown to become a leader in the manufacturing and supply of electric lead melting furnaces in China and beyond.The company's success can be attributed to several factors, one of which is their unwavering dedication to producing high-quality products. Every lead melting furnace that comes out of their factories is meticulously crafted by a team of skilled technicians and engineers. The company also incorporates the latest technological advancements in their manufacturing processes, ensuring that their products are not only of superior quality but also highly efficient and reliable.Furthermore, the company places a strong emphasis on research and development, constantly seeking new ways to improve their products and meet the evolving needs of their customers. This commitment to innovation has enabled them to stay ahead of the competition and remain a top choice for businesses in need of lead melting furnaces.In addition to their impressive manufacturing capabilities, China Electric Lead Melting Furnace Factories also prides itself on its exceptional customer service. The company understands the importance of building strong relationships with their clients, and as such, they go above and beyond to ensure that every customer is satisfied with their purchase. From the initial inquiry to after-sales support, the company's team is highly responsive and always willing to assist in any way they can.The company's dedication to quality and customer satisfaction has not gone unnoticed, as they have received accolades and recognition for their outstanding work. Their lead melting furnaces are highly sought after by businesses in various industries, including metal processing, recycling, and manufacturing. With a proven track record of delivering top-notch products and services, China Electric Lead Melting Furnace Factories has solidified its position as a reputable and reliable company in the industry.Looking ahead, the company is not content with resting on its laurels. They are continuously exploring new opportunities for growth and expansion, both domestically and internationally. With an eye on global markets, China Electric Lead Melting Furnace Factories is eager to introduce their exceptional products to a wider audience and make an even greater impact on the industry.In the midst of their ongoing success, the company remains committed to upholding their core values of integrity, excellence, and innovation. They understand that their reputation is only as strong as their last customer interaction, and as such, they continue to hold themselves to the highest standards of professionalism and quality.In conclusion, China Electric Lead Melting Furnace Factories has set the bar high for the manufacturing and supply of electric lead melting furnaces. Their unwavering commitment to excellence, combined with their dedication to customer satisfaction, has earned them a well-deserved reputation as a leader in the industry. As they continue to grow and expand their reach, there is no doubt that the company will maintain its position at the forefront of innovation and quality in the field of lead melting furnaces.

Digital Electric Melting Furnace Manufacturer in China

Title: China's Leading Digital Electric Melting Furnace Manufacturer Revolutionizes the Industry with High-Quality and Efficient SolutionsIntroduction: With the increasing demand for advanced manufacturing technologies, China's digital electric melting furnace industry has been rapidly evolving to meet the needs of various sectors. Amongst the notable manufacturers, one company stands out for its innovative solutions, superior quality, and commitment to sustainability. Leveraging cutting-edge technology, the China-based manufacturer has been at the forefront of transforming the melting furnace industry by introducing diverse products that cater to a wide range of industrial applications.Article:(Opening paragraph)Digital electric melting furnace manufacturer, (brand name removed), has been a trusted industry leader in China for several years. Established with a vision to provide efficient and sustainable solutions, the company has successfully paved its way to become one of the most reputable manufacturers in the market. Focusing on advanced technologies, precision engineering, and superior performance, (brand name removed) has revolutionized the melting furnace industry.(Body paragraphs)1. Technology-Driven Innovations:Setting itself apart from traditional melting furnaces, (brand name removed) has embraced digitalization and automation to enhance the overall efficiency and productivity of its products. Employing state-of-the-art technology, such as IoT integration and smart controls, the company ensures precise temperature controls, reduced energy consumption, and minimal heat loss. These innovations result in significant cost savings for businesses while reducing their carbon footprint.2. Wide Range of Applications:Recognizing the diverse needs of its customers, (brand name removed) offers a comprehensive range of digital electric melting furnaces suitable for various industries. Whether it is for the production of metals, alloys, or specialized materials, the company's furnaces provide consistent and reliable performance. Additionally, these furnaces offer flexibility in terms of melting capacity, allowing businesses of all sizes to benefit from their advanced manufacturing capabilities.3. Enhanced Safety and Durability:Safety is a paramount concern in industrial settings, and (brand name removed) upholds this principle by incorporating multiple safety features in their melting furnace designs. From advanced insulation technology to automatic shutdown mechanisms, the company ensures that the furnaces are reliable, secure, and easy to operate. Moreover, (brand name removed) guarantees the longevity of their products through a combination of high-quality materials and rigorous quality control measures, offering customers peace of mind and long-term value.4. Commitment to Sustainability:In an era of increased environmental consciousness, (brand name removed) stands out for its dedication to sustainable manufacturing practices. By leveraging energy-efficient designs and environmentally friendly materials, the company reduces energy consumption and minimizes harmful emissions. Furthermore, (brand name removed) emphasizes recycling and waste reduction while actively engaging in research and development to further enhance its products' eco-friendly attributes.5. Customer-Centric Approach:Setting itself apart from competitors, (brand name removed) is renowned for its commitment to exceptional customer service. The company's knowledgeable and responsive staff ensures prompt answers to customer inquiries and provides expert assistance throughout the buying process. Furthermore, (brand name removed) offers customizable solutions to meet specific requirements, further strengthening its relationship with clients and supporting their long-term success.(Conclusion)As the leading digital electric melting furnace manufacturer in China, (brand name removed) sets an impressive benchmark for the industry. With their innovative technologies, focus on sustainability, and customer-centric approach, the company continues to provide high-quality and efficient solutions to industrial sectors worldwide. As the manufacturing landscape evolves, (brand name removed) stands ready to meet emerging trends and challenges, remaining at the forefront of the industry's progress.

Top 5 Efficient Aluminium Casting Furnaces for Industrial Use

Title: Cutting-Edge Aluminium Casting Furnace Revolutionizes Manufacturing ProcessesIntroduction:In a groundbreaking development, a leading manufacturing company has unveiled its latest innovation in the realm of aluminium casting furnaces. By removing the brand name, we can shed light on the remarkable technology that promises to transform the industry. This revolutionary furnace incorporates cutting-edge features that optimize efficiency, precision, and sustainability within the aluminum casting process, progressively elevating the standards of manufacturing across sectors worldwide.Unveiling an Innovation:With a deep understanding of the metallurgical processes involved in aluminium casting, the company has introduced an advanced furnace design that pushes the boundaries of conventional methodologies. The newly developed furnace redefines speed, accuracy, and energy efficiency, creating a paradigm shift in the industry.Enhanced Efficiency:The updated aluminium casting furnace utilizes advanced software algorithms to regulate temperature, ensuring optimal melting and casting conditions. This precise temperature control not only reduces energy consumption but also results in faster heating and cooling cycles, significantly increasing overall productivity.Furthermore, the improved furnace promotes seamless metal flow during casting operations, minimizing the occurrence of defects and rework. By enhancing efficiency, the new design allows manufacturers to increase their output while reducing costs, ultimately resulting in higher profit margins.Unmatched Precision:To further elevate the quality of aluminium castings, the redesigned furnace incorporates state-of-the-art monitoring and control systems. These systems leverage advanced sensors to provide real-time data on critical parameters such as temperature, pressure, and metal composition. By maintaining tighter control over these factors, manufacturers can achieve precise and consistent casting results, eliminating product variations.The incorporation of predictive analytics allows operators to identify potential issues before they arise, reducing downtime and optimizing production schedules. The cutting-edge technology employed in this aluminium casting furnace enables manufacturers to deliver high-quality products that meet the stringent specifications demanded by modern industries.Sustainability at the Core:Recognizing the importance of sustainable manufacturing practices, the company has prioritized eco-friendliness throughout the design, development, and operation of the redesigned furnace. By virtue of its improved energy efficiency and reduced waste generation, the new furnace significantly lowers the carbon footprint associated with aluminum casting.Furthermore, the furnace incorporates advanced filtration systems that ensure the capture and removal of harmful emissions, reducing environmental impact. By investing in this technologically advanced equipment, manufacturers can align themselves with global sustainability goals, contributing to a greener and more sustainable future.Market Impact and Future Prospects:The introduction of this game-changing aluminium casting furnace is expected to disrupt the industry and fuel an era of innovation and growth. Manufacturers across sectors, including automotive, aerospace, and construction, are set to benefit from the enhanced efficiency, precision, and sustainability that this revolutionary technology offers.As the demand for superior quality aluminum products continues to rise, companies that embrace this advanced furnace technology will gain a competitive edge over their peers. The improved efficiency and production capabilities will accelerate the delivery of high-quality products, meeting market demands effectively.Looking ahead, the innovative design of this aluminium casting furnace sets the stage for further advancements in the field. The incorporation of artificial intelligence, automation, and robotics holds immense potential to streamline operations and redefine manufacturing standards in the years to come.Conclusion:Undeniably, the introduction of this advanced aluminium casting furnace represents a significant milestone for manufacturers aiming to enhance their productivity, precision, and sustainability. By removing the brand name, we have highlighted the impressive features and benefits that this groundbreaking technology brings to the industry. This furnace showcases the relentless pursuit of excellence and the commitment to innovation that drives the manufacturing sector forward.

Guide to Buying the Best Melting Furnace for Aluminum Scrap Recycling

Aluminum Scrap Melting Furnace Revolutionizes Recycling Industry: A Breakthrough Innovation[Company Name], a leading pioneer in the field of recycling solutions, has recently unveiled their latest innovation, the Aluminum Scrap Melting Furnace. With the goal of revolutionizing the recycling industry, this state-of-the-art furnace is set to redefine the process of aluminum scrap melting and significantly enhance the efficiency and sustainability of recycling aluminum.Sustainability and environmental consciousness have become increasingly vital concerns in recent years. The call for more efficient recycling methods has grown louder, with aluminum being one of the most widely recycled materials due to its high value and endless recyclability. [Company Name] recognizes the urgency to improve and optimize the recycling process, leading them to develop the Aluminum Scrap Melting Furnace.The Aluminum Scrap Melting Furnace is designed to provide an innovative solution to the challenges faced by conventional melting processes. By combining advanced technology and groundbreaking engineering, [Company Name] has developed a furnace that is capable of melting aluminum scrap at an unprecedented speed while minimizing energy consumption.One of the primary features that set this furnace apart is its advanced heating system. Unlike traditional furnaces that rely on fossil fuels, the Aluminum Scrap Melting Furnace utilizes a cutting-edge electric heating system. This not only makes the process more environmentally friendly by reducing greenhouse gas emissions, but also provides enhanced precision and control over the melting process.The furnace is equipped with a sophisticated control panel, allowing operators to set and monitor the required temperature accurately. The efficiency of this furnace is further elevated by automated temperature control and feedback mechanisms, ensuring optimal melting conditions and reducing the risk of overheating or wastage.Moreover, the Aluminum Scrap Melting Furnace is engineered to accommodate a wide range of aluminum scrap, from various alloys to different shapes and sizes. Its versatility enables recycling facilities to process diverse types of scrap efficiently, maximizing the utilization of resources and reducing the amount of aluminum ending up in landfills.The furnace's ergonomic design also aims to improve the overall working conditions in recycling plants. With user-friendly features and advanced safety mechanisms, such as automated lid opening and closing, operators can carry out their tasks with ease while minimizing the risk of accidents or injuries.In addition to its remarkable functionality, the Aluminum Scrap Melting Furnace boasts a compact and modular design. This allows for easy installation and integration into existing recycling facilities, minimizing downtime and increasing operational efficiency. The furnace's modular nature also enables scalability, providing recycling plants the flexibility to expand their capacity as needed without significant disruptions.[Company Name]'s Aluminum Scrap Melting Furnace is not only a game-changer for recycling facilities but also a substantial step towards a more sustainable future. By improving the efficiency and effectiveness of aluminum scrap melting, this furnace contributes to the conservation of valuable resources and reduces the environmental impact of the recycling process.With concerns about climate change and the importance of transitioning to a circular economy, the Aluminum Scrap Melting Furnace represents a significant breakthrough in recycling technology. [Company Name] continues to push the boundaries of innovation, setting new benchmarks for sustainability and resource optimization, and solidifying its position as a leader in the recycling industry.In conclusion, the Aluminum Scrap Melting Furnace developed by [Company Name] is set to revolutionize the recycling industry. This cutting-edge furnace enhances the efficiency and sustainability of aluminum scrap melting, utilizing advanced electric heating technology, precision control mechanisms, and modular design. By implementing this innovative solution, recycling facilities can significantly reduce energy consumption, minimize waste, and contribute to a greener and more sustainable future.