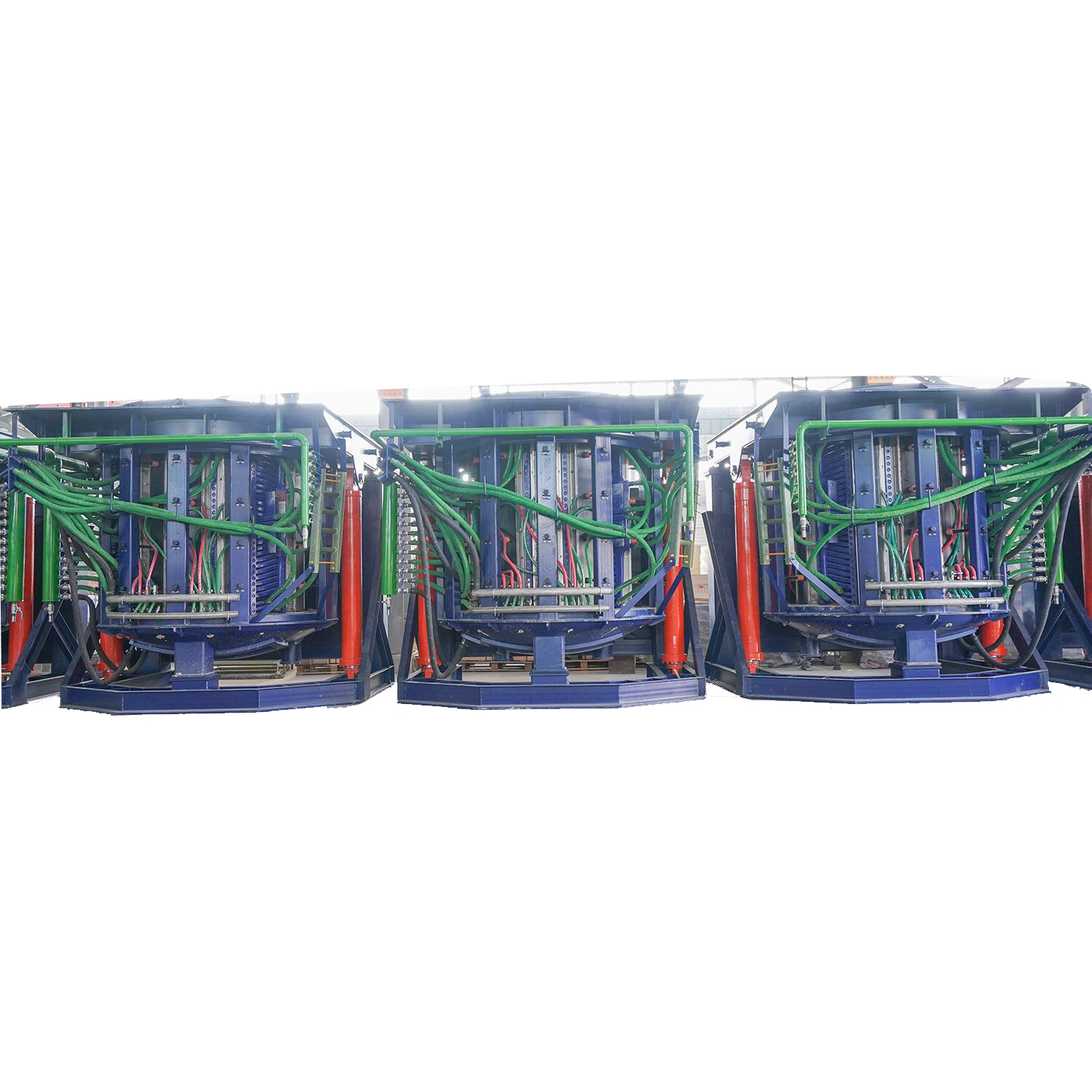

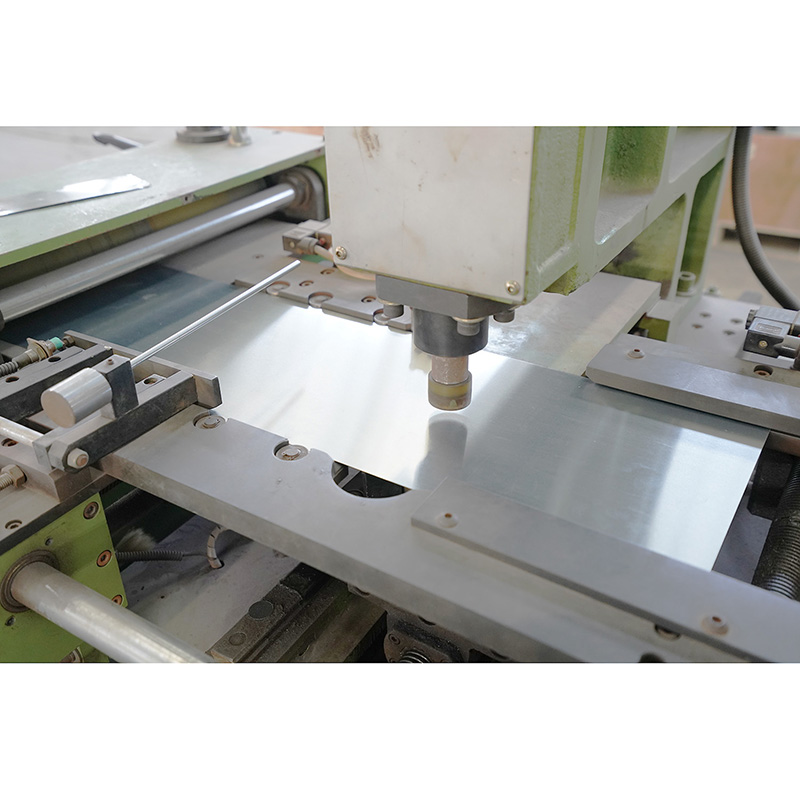

The induction coil is the core component of the intermediate frequency electric furnace. After being energized, an eddy current is generated in the middle, and the metal placed in it is heated and melted rapidly. It is an executive component that heats, melts, and heats up the charge to provide energy. Its quality directly affects whether the charge can be heated quickly, whether it can achieve the expected goal, and whether the whole set of equipment can operate normally. The induction coil produced by our company refers to It is accumulated from domestic and foreign design data and years of experience data. After optimizing the design with a microcomputer, determine its basic parameters, such as the number of turns, copper tube specifications, the ratio of height to diameter, etc., to maximize the electrical efficiency. The entire induction coil has been shot blasted, passivated and picked. The conductivity and cooling effect are more superior, preventing the coil from being oxidized and clogged during use. The contact parts of the copper pipes are all insulated by high temperature resistant insulating materials. Our company's products have spread to most provinces and regions in the country, and some products are exported to Southeast Asia, West Asia, Central Asia, Africa and other places. The equipment far exceeds the general industrial standard in terms of operating efficiency, quality and reliability.

The induction coil is the core component of the intermediate frequency electric furnace. After being energized, an eddy current is generated in the middle, and the metal placed in it is heated and melted rapidly. It is an executive component that heats, melts, and heats up the charge to provide energy. Its quality directly affects whether the charge can be heated quickly, whether it can achieve the expected goal, and whether the whole set of equipment can operate normally. The induction coil produced by our company refers to It is accumulated from domestic and foreign design data and years of experience data. After optimizing the design with a microcomputer, determine its basic parameters, such as the number of turns, copper tube specifications, the ratio of height to diameter, etc., to maximize the electrical efficiency. The entire induction coil has been shot blasted, passivated and picked. The conductivity and cooling effect are more superior, preventing the coil from being oxidized and clogged during use. The contact parts of the copper pipes are all insulated by high temperature resistant insulating materials. Our company's products have spread to most provinces and regions in the country, and some products are exported to Southeast Asia, West Asia, Central Asia, Africa and other places. The equipment far exceeds the general industrial standard in terms of operating efficiency, quality and reliability.Induction Coil INDUCTION FURNACE

Find high-quality Induction Coils for Induction Furnaces at our factory. We offer excellent manufacturing expertise and top-notch products. Visit us now!

Request a QuotePRODUCTS DETAILS

The induction coil is the core component of the intermediate frequency electric furnace. After being energized, an eddy current is generated in the middle, and the metal placed in it is heated and melted rapidly. It is an executive component that heats, melts, and heats up the charge to provide energy. Its quality directly affects whether the charge can be heated quickly, whether it can achieve the expected goal, and whether the whole set of equipment can operate normally. The induction coil produced by our company refers to It is accumulated from domestic and foreign design data and years of experience data. After optimizing the design with a microcomputer, determine its basic parameters, such as the number of turns, copper tube specifications, the ratio of height to diameter, etc., to maximize the electrical efficiency. The entire induction coil has been shot blasted, passivated and picked. The conductivity and cooling effect are more superior, preventing the coil from being oxidized and clogged during use. The contact parts of the copper pipes are all insulated by high temperature resistant insulating materials. Our company's products have spread to most provinces and regions in the country, and some products are exported to Southeast Asia, West Asia, Central Asia, Africa and other places. The equipment far exceeds the general industrial standard in terms of operating efficiency, quality and reliability.

The induction coil is the core component of the intermediate frequency electric furnace. After being energized, an eddy current is generated in the middle, and the metal placed in it is heated and melted rapidly. It is an executive component that heats, melts, and heats up the charge to provide energy. Its quality directly affects whether the charge can be heated quickly, whether it can achieve the expected goal, and whether the whole set of equipment can operate normally. The induction coil produced by our company refers to It is accumulated from domestic and foreign design data and years of experience data. After optimizing the design with a microcomputer, determine its basic parameters, such as the number of turns, copper tube specifications, the ratio of height to diameter, etc., to maximize the electrical efficiency. The entire induction coil has been shot blasted, passivated and picked. The conductivity and cooling effect are more superior, preventing the coil from being oxidized and clogged during use. The contact parts of the copper pipes are all insulated by high temperature resistant insulating materials. Our company's products have spread to most provinces and regions in the country, and some products are exported to Southeast Asia, West Asia, Central Asia, Africa and other places. The equipment far exceeds the general industrial standard in terms of operating efficiency, quality and reliability.Hot Products

60T Induction Melting Furnace

Water Cooled Cable Yinda Induction Furnace

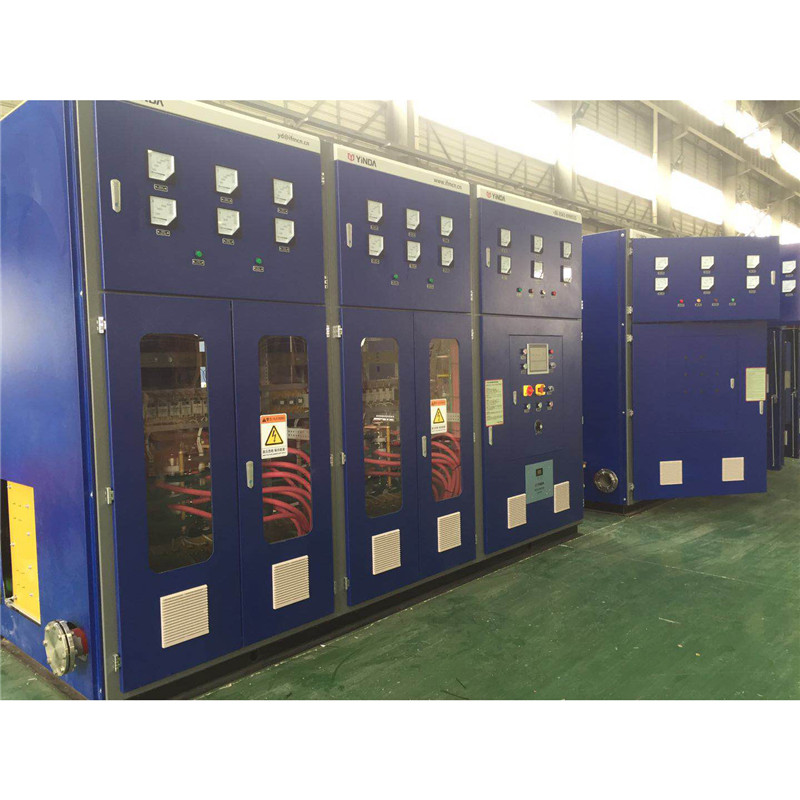

Medium frequency power cabinet

Premium Quality PLC Cabinets

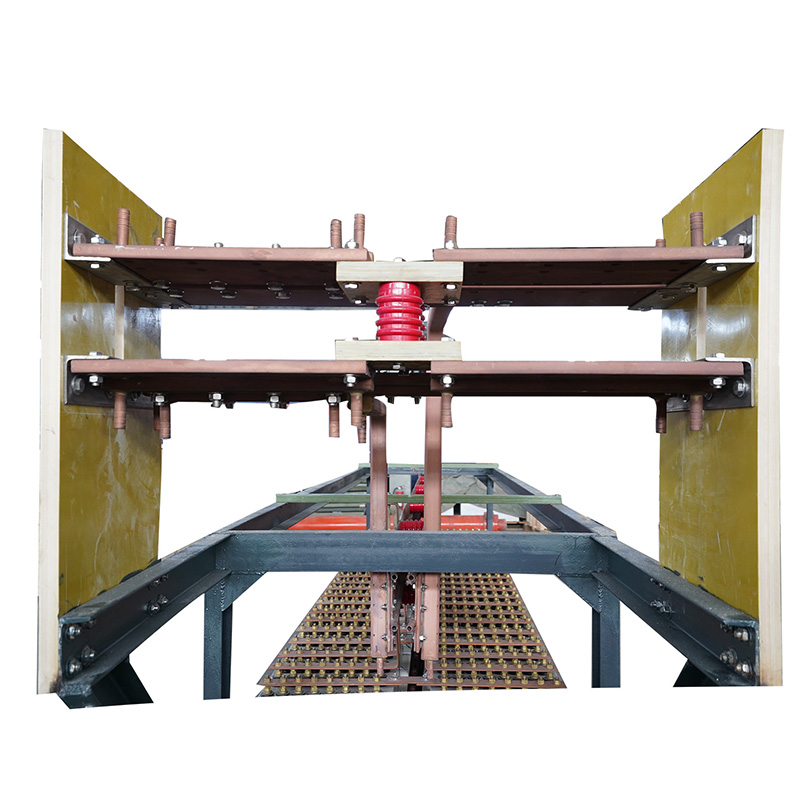

Magnet Yoke For Smelting Furnace

The Hydraulic Pressure Stands

High-quality Capacitors for Induction Furnace

Power Supply Yinda Induction Furnace

Induction Coil INDUCTION FURNACE

Oil Dry Type Reactor For Induction Melting Furnace

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours