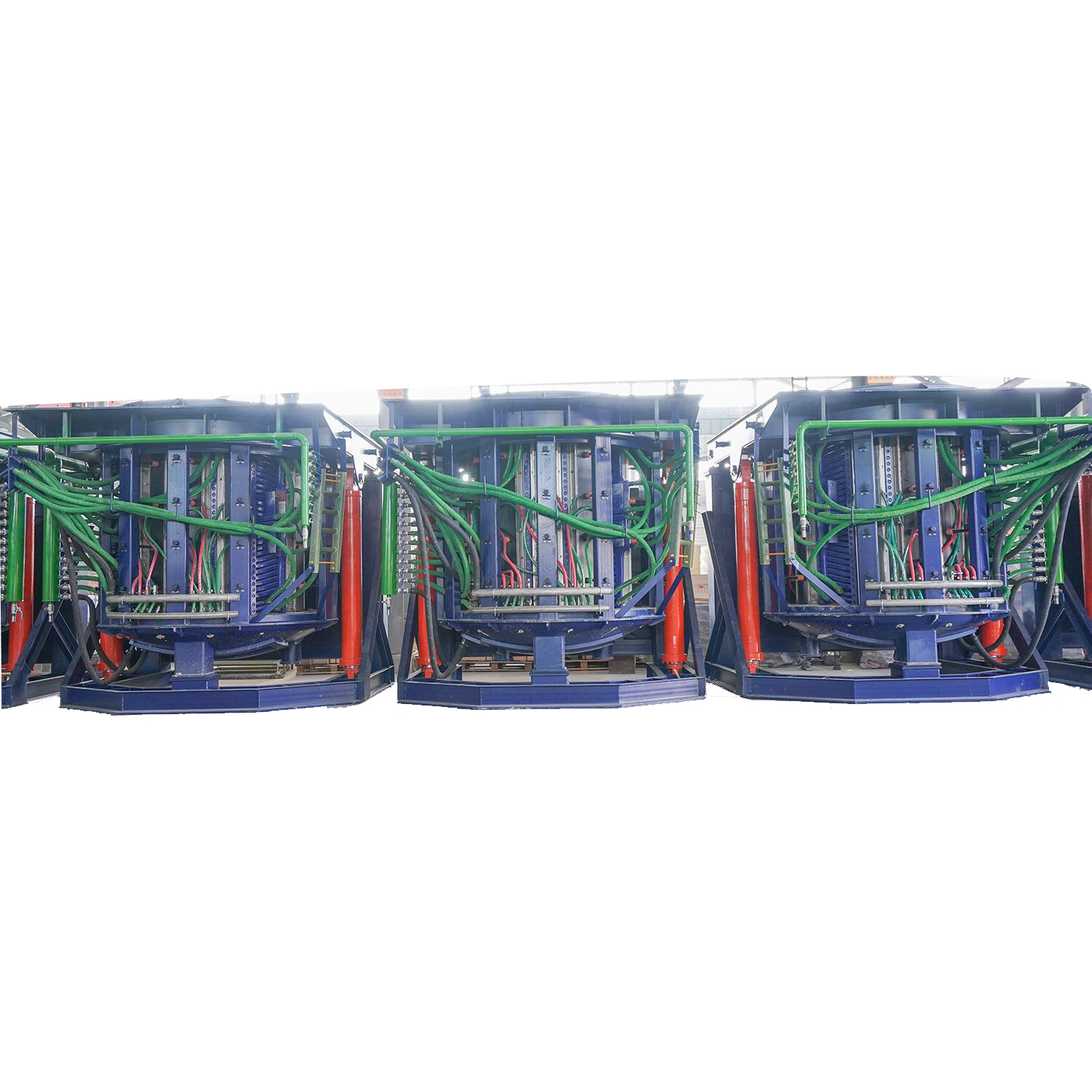

Selection method of intermediate frequency furnace capacitor bank: The intermediate frequency furnace compensation capacitor cabinet is welded by channel steel and angle steel, and is equipped with a safety net to make the overall structure strong and beautiful. The insulator of the capacitor is treated with a double-layer cloud mold insulation technology, even if the water is accidentally removed. Spraying on the capacitor can also ensure the insulation strength of the cabinet. In order to reduce the loss of the large current loop, the compensation capacitor bank is installed in the basement as close as possible to the electric furnace. The capacitors all adopt new large-capacity non-toxic and water-cooled RFM series electrothermal capacitors, which have the advantages of large monomer, low dielectric loss, and small footprint. The capacitor cabinet is installed closest to the furnace body, which can reduce the loss of the tank circuit and improve efficiency.The product quality is excellent, the performance is stable, and the after-sales service is perfect. The products sell well in all provinces, cities, regions and some Southeast Asian markets! We will always adhere to the principle of high quality, high price and excellent after-sales service to strengthen cooperation with all new and old customers and develop together. We warmly welcome new and old customers to visit our company!

Selection method of intermediate frequency furnace capacitor bank: The intermediate frequency furnace compensation capacitor cabinet is welded by channel steel and angle steel, and is equipped with a safety net to make the overall structure strong and beautiful. The insulator of the capacitor is treated with a double-layer cloud mold insulation technology, even if the water is accidentally removed. Spraying on the capacitor can also ensure the insulation strength of the cabinet. In order to reduce the loss of the large current loop, the compensation capacitor bank is installed in the basement as close as possible to the electric furnace. The capacitors all adopt new large-capacity non-toxic and water-cooled RFM series electrothermal capacitors, which have the advantages of large monomer, low dielectric loss, and small footprint. The capacitor cabinet is installed closest to the furnace body, which can reduce the loss of the tank circuit and improve efficiency.The product quality is excellent, the performance is stable, and the after-sales service is perfect. The products sell well in all provinces, cities, regions and some Southeast Asian markets! We will always adhere to the principle of high quality, high price and excellent after-sales service to strengthen cooperation with all new and old customers and develop together. We warmly welcome new and old customers to visit our company!High-quality Capacitors for Induction Furnace

Shop high-quality capacitors for induction furnace at our factory. Increase efficiency and reduce energy consumption. Order now for reliable performance.

Request a QuotePRODUCTS DETAILS

Selection method of intermediate frequency furnace capacitor bank: The intermediate frequency furnace compensation capacitor cabinet is welded by channel steel and angle steel, and is equipped with a safety net to make the overall structure strong and beautiful. The insulator of the capacitor is treated with a double-layer cloud mold insulation technology, even if the water is accidentally removed. Spraying on the capacitor can also ensure the insulation strength of the cabinet. In order to reduce the loss of the large current loop, the compensation capacitor bank is installed in the basement as close as possible to the electric furnace. The capacitors all adopt new large-capacity non-toxic and water-cooled RFM series electrothermal capacitors, which have the advantages of large monomer, low dielectric loss, and small footprint. The capacitor cabinet is installed closest to the furnace body, which can reduce the loss of the tank circuit and improve efficiency.The product quality is excellent, the performance is stable, and the after-sales service is perfect. The products sell well in all provinces, cities, regions and some Southeast Asian markets! We will always adhere to the principle of high quality, high price and excellent after-sales service to strengthen cooperation with all new and old customers and develop together. We warmly welcome new and old customers to visit our company!

Selection method of intermediate frequency furnace capacitor bank: The intermediate frequency furnace compensation capacitor cabinet is welded by channel steel and angle steel, and is equipped with a safety net to make the overall structure strong and beautiful. The insulator of the capacitor is treated with a double-layer cloud mold insulation technology, even if the water is accidentally removed. Spraying on the capacitor can also ensure the insulation strength of the cabinet. In order to reduce the loss of the large current loop, the compensation capacitor bank is installed in the basement as close as possible to the electric furnace. The capacitors all adopt new large-capacity non-toxic and water-cooled RFM series electrothermal capacitors, which have the advantages of large monomer, low dielectric loss, and small footprint. The capacitor cabinet is installed closest to the furnace body, which can reduce the loss of the tank circuit and improve efficiency.The product quality is excellent, the performance is stable, and the after-sales service is perfect. The products sell well in all provinces, cities, regions and some Southeast Asian markets! We will always adhere to the principle of high quality, high price and excellent after-sales service to strengthen cooperation with all new and old customers and develop together. We warmly welcome new and old customers to visit our company!Hot Products

60T Induction Melting Furnace

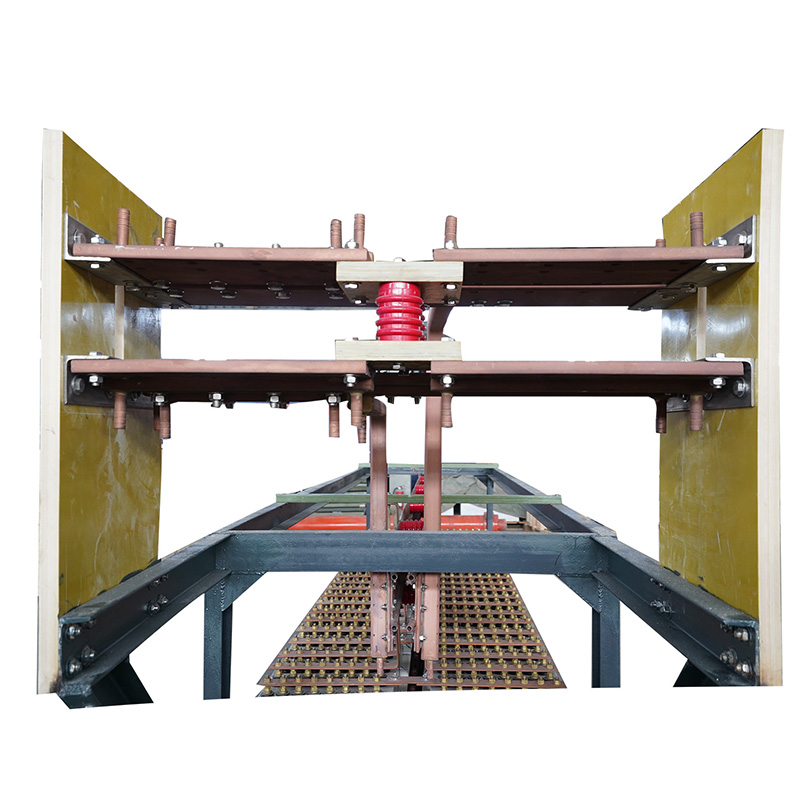

Magnet Yoke For Smelting Furnace

The Hydraulic Pressure Stands

High-quality Capacitors for Induction Furnace

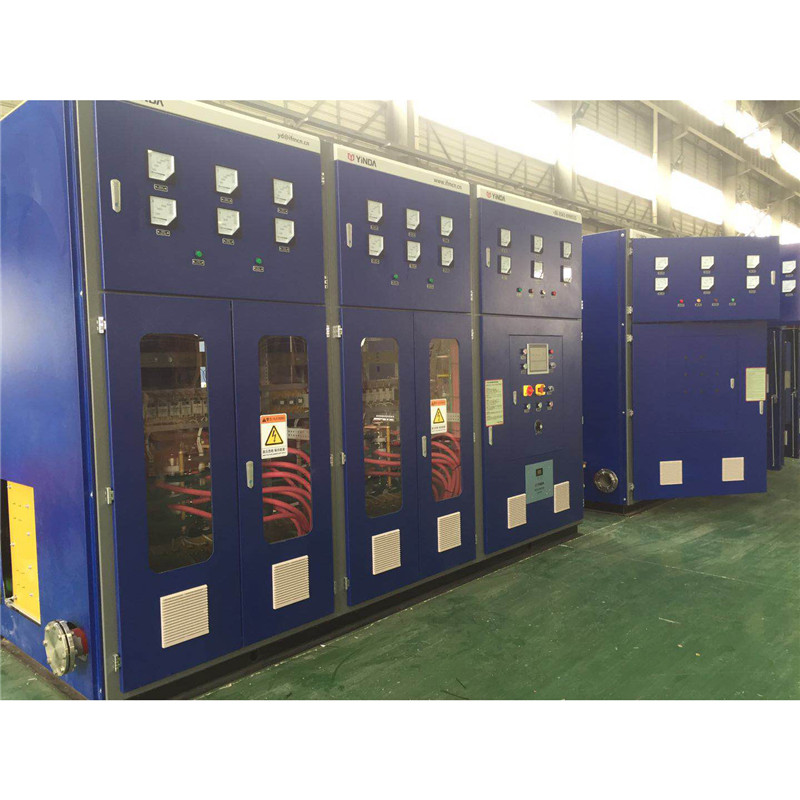

Medium frequency power cabinet

Water Cooled Cable Yinda Induction Furnace

Oil Dry Type Reactor For Induction Melting Furnace

Premium Quality PLC Cabinets

Induction Coil INDUCTION FURNACE

Power Supply Yinda Induction Furnace

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours