Groundbreaking Discovery Unveils New Potential in Foundry Induction Technology

By:Admin

Introduction:

In today's rapidly advancing industrial landscape, innovation and technological advancements continue to redefine manufacturing processes across various sectors. In line with this trend, a groundbreaking technology has emerged in the foundry industry, promising unprecedented efficiencies and environmental benefits. This revolutionary induction technology, developed and commercialized by a pioneering industry leader, is set to transform the landscape of foundry operations worldwide.

Background:

The foundry industry has traditionally relied heavily on fossil fuel-powered furnaces to melt metal alloys for casting processes. Though effective, these traditional methods are environmentally taxing, generating significant greenhouse gas emissions and consuming large quantities of non-renewable resources. With growing concerns over climate change and sustainability, there has been a pressing need for forward-thinking solutions that address these issues without sacrificing operational efficiency.

Induction Technology: A Paradigm Shift

Enter the groundbreaking induction technology, a transformative breakthrough that promises to redefine the foundry sector. The technology enables the melting of metal alloys through electromagnetic induction, rather than relying on conventional fossil fuel heating sources. This process significantly reduces the carbon footprint of the foundry industry, making it more sustainable and environmentally friendly.

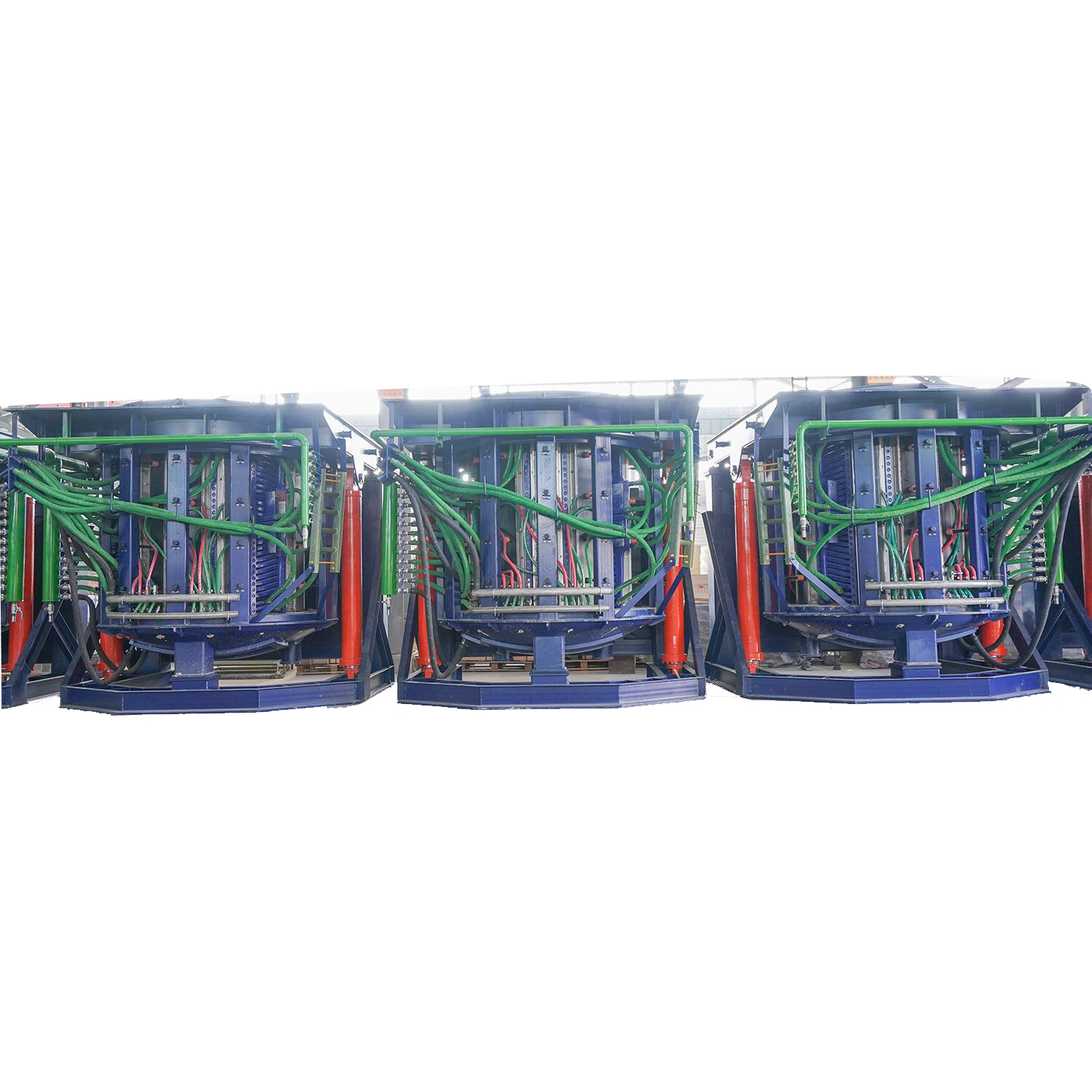

Induction Foundry: Leader in Revolutionizing Casting Processes

One prominent industry player at the forefront of this transformation is Induction Foundry (name removed). As a leading innovator and manufacturer of induction equipment, the company has played a pivotal role in driving the adoption of this game-changing technology. By combining expertise in metallurgy, engineering, and sustainable practices, Induction Foundry has introduced a range of highly efficient induction furnaces and equipment that have garnered worldwide acclaim.

Increased Efficiency and Cost Savings

Induction Foundry's cutting-edge induction furnaces boast several advantages over conventional melting techniques. Firstly, the technology offers unparalleled energy efficiency, significantly reducing operating costs compared to traditional furnaces. Induction furnaces achieve optimal melting temperatures faster, resulting in shorter cycle times, increased productivity, and reduced energy consumption. The electromagnetic induction process also allows more precise temperature control, ensuring consistent casting quality and minimizing material waste.

Environmental Sustainability at the Core

Induction Foundry's environmentally conscious equipment aligns well with the global sustainability movement. By eliminating fossil fuel combustion, the company's induction furnaces minimize emissions, improve air quality, and help combat climate change. Additionally, the induction process generates significantly less waste compared to traditional methods, as it avoids the need for refractory materials. These sustainable features have positioned Induction Foundry as a responsible industry leader, garnering acclaim and recognition from environmental organizations.

A Future-Proofed Foundry Industry

With environmental regulations becoming increasingly stringent and consumers demanding products manufactured through sustainable processes, the foundry industry must adapt rapidly. Induction technology offers the perfect solution - a highly efficient, sustainable, and cost-effective alternative to conventional melting processes. By embracing induction technology, foundry operators can modernize their facilities, enhance operational efficiency, and gain a competitive edge in the market.

Global Adoption and Growth Potential

Induction Foundry's induction furnaces have witnessed substantial adoption across the globe. Foundries in various industries, such as automotive, aerospace, and machinery manufacturing, have implemented this transformational technology. The positive feedback and success stories from early adopters have further accelerated the growth potential of the induction foundry industry.

Conclusion:

As the global focus on sustainability intensifies, the foundry industry must embrace new and innovative technologies to stay ahead of the curve. Induction Foundry's pioneering induction technology presents a transformative opportunity for foundries worldwide to enhance productivity, reduce costs, and minimize environmental impact. With a growing customer base, Induction Foundry's induction furnaces are setting new benchmarks for the foundry industry while paving the way for a more sustainable future.

Company News & Blog

China's Leading Electric Lead Melting Furnace Factories

China Electric Lead Melting Furnace Factories Boost Lead Recycling EffortsIn recent years, there has been a growing concern about the impact of lead on the environment and human health. Lead, a toxic heavy metal, can contaminate soil, water, and even air, posing significant risks to living organisms. In response to these concerns, China Electric Lead Melting Furnace Factories have made great strides in developing and manufacturing advanced lead melting furnaces that enable efficient lead recycling.China Electric Lead Melting Furnace Factories have been at the forefront of promoting sustainable practices in lead processing. By creating cutting-edge lead melting furnaces, these factories are providing an eco-friendly solution to the increasing demand for lead recycling. The advanced technology employed in these furnaces allows for better control and regulation of the melting process, resulting in higher purity lead and reduced emissions.Lead recycling plays a vital role in reducing environmental pollution and conserving natural resources. Through the use of electric lead melting furnaces, lead-acid batteries, which contain large amounts of lead, can be efficiently and safely recycled. The lead melting furnaces are designed to handle the specific requirements of lead recycling, ensuring the conversion of lead into reusable materials.Apart from environmental benefits, lead recycling also presents economic opportunities. The demand for lead is continuously increasing, driven by various industries such as automotive, construction, and electronics. By investing in advanced lead melting furnaces, China Electric Lead Melting Furnace Factories are not only fulfilling the need for lead but also contributing to the circular economy. These furnaces enable the extraction of lead from secondary sources, decreasing dependency on virgin raw materials and reducing production costs.Furthermore, China Electric Lead Melting Furnace Factories prioritize safety in their operations. The lead melting furnaces are equipped with advanced safety features and automated control systems, minimizing the risk of accidents and ensuring a safe working environment. The factories strictly adhere to international safety standards and regulations, guaranteeing that their products meet the highest quality and safety requirements.The company behind these innovative lead melting furnaces traces its origins back several decades. Established with the vision of providing sustainable solutions for lead processing, the company has grown into a prominent player in the industry. With a strong focus on research and development, they continuously strive to enhance their products' performance and efficiency.The commitment of China Electric Lead Melting Furnace Factories to sustainable lead recycling is commendable. By manufacturing state-of-the-art lead melting furnaces, they promote environmental protection, resource conservation, and economic growth simultaneously. Their efforts align with China's broader goals of transitioning towards a greener and more sustainable economy.Looking ahead, China Electric Lead Melting Furnace Factories plan to further expand their product lineup, catering to the evolving needs of the lead recycling industry. They intend to develop furnaces with even higher energy efficiency and lower emissions, ensuring that the recycling process becomes even more environmentally friendly.In conclusion, China Electric Lead Melting Furnace Factories are playing a significant role in advancing lead recycling efforts in China. Through the development and manufacturing of advanced lead melting furnaces, these factories enable the safe and efficient recycling of lead, reducing environmental pollution and conserving valuable resources. Their dedication to sustainability and commitment to producing high-quality and safe products make them a key player in the global lead processing industry.

Discover an Efficient Solution for Your Furnace Needs

Title: Next-Generation Furnace Showcases Groundbreaking Innovations in Casting IndustryIntroduction:In a bid to revolutionize the casting industry, a renowned furnace manufacturer has unveiled its latest product, the groundbreaking Cast Master Furnace. This state-of-the-art furnace is set to redefine the standards of casting technology with its advanced features and efficient performance. The new Cast Master Furnace signifies a significant leap forward, promising unparalleled precision, productivity, and sustainability for casting professionals worldwide.1. Advanced Technology Enhancing Precision:The Cast Master Furnace integrates cutting-edge technology to provide a higher level of precision in the casting process. Incorporating advanced sensors and sophisticated software, the furnace ensures accurate temperature control, preventing overheating or underheating of the metal alloys. This breakthrough technology guarantees exceptional product quality and reduces wastage, enabling casting professionals to achieve the desired results consistently.Furthermore, the furnace's innovative design enables precise monitoring of various parameters such as gas flow, pressure, and air ratios, ensuring optimized combustion. This not only enhances energy efficiency but also minimizes environmental impact, making the Cast Master Furnace a sustainable choice for casting operations.2. Increased Productivity with Smart Features:Recognizing the importance of productivity in the casting industry, the Cast Master Furnace offers a host of smart features that streamline the casting process and reduce downtime. The inclusion of remote monitoring capabilities allows operators to track the furnace's performance, identify potential issues, and make real-time adjustments from a centralized control panel. This remote operation feature enhances efficiency and reduces the need for manual intervention, resulting in improved productivity levels.In addition to remote monitoring, the Cast Master Furnace incorporates an intelligent scheduling system that optimizes the casting cycle based on various factors like alloy composition, mold complexity, and cooling requirements. By automating the scheduling process, the furnace allows for efficient use of resources, thereby maximizing productivity and reducing production costs.3. Sustainability and Energy Efficiency:The Cast Master Furnace is designed to promote sustainable practices and reduce energy consumption in the casting industry. Utilizing state-of-the-art insulation materials, the furnace minimizes heat loss, improving energy efficiency while ensuring a safer working environment.Moreover, the furnace employs a multi-stage filtration system to capture and treat harmful emissions, significantly reducing pollutants released into the atmosphere. This commitment to environmental responsibility aligns with global efforts to mitigate the carbon footprint of industrial processes, making the Cast Master Furnace an environmentally-conscious choice.4. Collaborative Approach for Industry Advancement:The introduction of the Cast Master Furnace demonstrates the manufacturer's commitment to fostering collaboration within the casting industry. The company has actively engaged with casting professionals, incorporating their valuable feedback and insights during the development phase. By combining extensive industry experience with cutting-edge technology, the manufacturer has addressed the specific challenges faced by casting professionals, resulting in an innovative furnace tailored to their unique requirements.Furthermore, the company offers comprehensive technical support, including training programs and prompt assistance from a team of experts. By nurturing a collaborative environment, the manufacturer strives to empower casting professionals with the necessary knowledge and skills to optimize their casting operations effectively.Conclusion:As the casting industry moves towards a more technologically advanced era, the Cast Master Furnace leads the way with its groundbreaking features, exceptional precision, and commitment to sustainability. This advanced furnace promises to revolutionize the casting process, enabling professionals to achieve higher levels of accuracy, productivity, and energy efficiency. With its innovative design and comprehensive support system, the Cast Master Furnace is set to become the choice of casting professionals worldwide, positioning the industry for a brighter and more sustainable future.

Top Crucible Factory in China for Induction Furnaces

China Induction Furnace Crucible Factory Leads the Way in High-Quality CruciblesChina Induction Furnace Crucible Factory, one of the leading manufacturers of high-quality crucibles, has been making significant strides in the production of premium quality crucibles that meet the needs of clients in various industries. The factory, which has been in operation for over 20 years, has become a household name in the industry, thanks to its commitment to innovation and quality.The factory's crucibles are used in a wide range of industries, including metallurgy, foundry, ceramics, chemical, and aerospace. The company has a reputation for producing reliable, cost-effective, and long-lasting crucibles that meet the needs of its clients.China Induction Furnace Crucible Factory uses advanced technology to manufacture its crucibles. The company uses a high-temperature oxidation process for its crucibles that ensures they can withstand high temperatures and pressure. Additionally, the factory has state-of-the-art equipment that allows it to produce crucibles with tight tolerances and accurate dimensions.The company's focus on innovation and quality has helped it to maintain its position as one of the leading crucible manufacturers in the industry. The factory continuously conducts research to develop new materials and production techniques that will help it to offer better products at lower costs. The company also invests heavily in training and development to ensure that its staff has the skills and knowledge needed to produce high-quality crucibles.In addition to producing high-quality crucibles, China Induction Furnace Crucible Factory also offers excellent customer service. The company has a team of professionals that are always ready and willing to answer clients' questions and help them choose the right crucibles for their needs. The team is also available to provide after-sales support to ensure that clients are satisfied with the products they purchase.The factory's commitment to quality is reflected in its ISO 9001 certification. The factory has a comprehensive quality control system that ensures that it meets its clients' requirements and standards. The company also uses high-quality raw materials to produce its crucibles, which guarantees the products' consistency and reliability.China Induction Furnace Crucible Factory's dedication to quality has earned it a loyal customer base, both locally and internationally. The factory exports its products to various countries, including the United States, Canada, and Europe. The company's reputation for producing high-quality crucibles has helped it to build long-lasting relationships with its clients.In conclusion, China Induction Furnace Crucible Factory is a leader in the production of high-quality crucibles. The company's commitment to quality, innovation, and customer service has helped it to maintain its reputation as one of the best crucible manufacturers in the industry. The factory's dedication to research and development ensures that it continues to produce better products at lower costs, making it a reliable partner for businesses in various industries.

China's Leading Suppliers of Melting Furnace Electric Equipment

China Melting Furnace Electric Suppliers Leading the Way in Energy-Saving Technology for the Metallurgical IndustryChina Melting Furnace Electric Suppliers (CMFES) is one of the leading providers of energy-efficient electric melting furnaces in China. The company has been serving the metallurgical industry for over a decade and has gained an excellent reputation for the quality and reliability of its products. CMFES is committed to developing innovative solutions that help its customers increase their productivity, reduce their energy consumption, and minimize their environmental impact.CMFES offers a wide range of electric melting furnaces that are designed to meet the specific needs of different types of metal processing applications. The company's product portfolio includes induction furnaces, arc furnaces, resistance furnaces, and other specialty furnaces. These furnaces are used for melting and casting various types of metals, such as steel, iron, copper, aluminum, and alloys. One of the key advantages of CMFES electric melting furnaces is their energy efficiency. The company uses advanced technologies to optimize the performance of its furnaces, such as high frequency induction heating, regenerative combustion, and automatic temperature control. These features help to reduce the energy consumption of the furnaces by up to 30%, compared to traditional melting methods. This not only saves energy but also lowers the operating costs of the customers, enabling them to stay competitive in the global market.Moreover, CMFES has a strong focus on environmental sustainability and has developed several solutions to address the challenges of reducing emissions and waste. For instance, the company's regenerative combustion technology enables the furnaces to recover waste heat and reuse it for the next melting cycle. This not only saves energy but also promotes cleaner air quality by reducing the amount of pollutants emitted into the atmosphere. CMFES also offers recycling solutions for the metal scraps generated from the melting process, ensuring that the materials are reused and not wasted.In addition to offering high-quality products, CMFES provides excellent customer support and after-sales service. The company has a team of experienced engineers and technicians who work closely with the customers to understand their specific requirements and provide customized solutions. CMFES also offers training and maintenance services, ensuring that the furnaces operate efficiently and safely over their lifespan.CMFES is committed to continuous innovation and has invested significant resources in R&D to develop new technologies and improve its existing products. The company collaborates with leading universities and research institutions to stay up-to-date with the latest trends and developments in the metallurgical industry. CMFES has a strong intellectual property portfolio and has obtained several patents for its inventions.Looking ahead, CMFES sees enormous growth potential in the global metallurgical market, especially in emerging economies where demand for metals is increasing rapidly. The company plans to expand its business globally and strengthen its partnerships with key customers and distributors. CMFES aims to become a leading player in the international melting furnace market, offering cutting-edge solutions that help customers achieve their business goals while contributing to a sustainable future for the planet.In conclusion, China Melting Furnace Electric Suppliers is an innovative company that is leading the way in energy-saving technology for the metallurgical industry. The company's commitment to sustainability and customer satisfaction has earned it a loyal following among its customers and a reputation as a trusted provider of high-quality melting furnaces. As the world's demand for metals continues to grow, CMFES is well-positioned to capitalize on this trend and drive sustainable growth for the benefit of all stakeholders.

Discover the Secrets of Steel Melting Forges for Efficient Metal Transformation

[News Content]Steel Melting Forge Facility Increases Production Capacity, Boosting Company's Competitive Advantage[City, Date] – In an effort to expand their production capabilities and enhance overall efficiency, [Company Name] has successfully commissioned a new steel melting forge facility at their manufacturing plant. With this strategic investment, the company aims to meet the growing demand for high-quality steel products and strengthen its position in the market.The state-of-the-art steel melting forge, equipped with cutting-edge technology, boasts an impressive range of features that streamline the production process. It offers precision control over the melting process, ensuring superior material quality and consistency. The facility is also designed to minimize energy consumption, leading to both environmental and cost-saving benefits.By investing in the new steel melting forge, [Company Name] is geared towards significantly increasing its production capacity. The facility's advanced automation systems allow for continuous and uninterrupted production, reducing downtime and optimizing output. This will enable the company to deliver orders to customers more efficiently and promptly, thereby improving customer satisfaction and maintaining a leading position in the industry.[Company Name], a renowned player in the steel manufacturing industry, has continuously strived to integrate the latest technological advancements into its operations. The introduction of the steel melting forge further reinforces the company's commitment to innovation and growth.With this new addition, [Company Name] aims to cater to a wider range of industries, including automotive, construction, and machinery manufacturing. The facility's ability to melt various grades of steel, such as carbon steel, stainless steel, and alloy steel, ensures that the company can meet diverse customer requirements in terms of material specifications and performance characteristics."Expanding our production capabilities is crucial to meeting the evolving needs of our customers," said [Company Name]'s CEO. "The steel melting forge facility will play a pivotal role in strengthening our market position and increasing our competitiveness."Moreover, the new facility aligns with [Company Name]'s commitment to sustainability and reducing its environmental footprint. By incorporating energy-efficient technologies into the steel melting process, the company aims to minimize carbon emissions and optimize resource utilization. This investment not only benefits the business but also demonstrates [Company Name]'s dedication to being a responsible corporate citizen.To uphold its high standards of quality assurance, [Company Name] has also invested in a comprehensive inspection and testing system within the steel melting forge facility. This system enables continuous monitoring of the molten steel composition, ensuring compliance with stringent quality control standards. By doing so, the company guarantees consistent product quality and reliability, reinforcing customer trust in its offerings.The new steel melting forge facility is expected to generate employment opportunities, benefiting both the local community and the wider economy. Its implementation showcases [Company Name]'s commitment to fostering economic growth through sustained investment and innovation.With the commissioning of the steel melting forge facility, [Company Name] is poised to solidify its position as a market leader in the steel manufacturing sector. The increased production capacity, along with enhanced operational efficiency, will enable the company to address market demands effectively and cater to a diverse customer base, ultimately driving its growth and success.About [Company Name]:[Company Name] is a globally recognized steel manufacturing company, dedicated to delivering high-quality steel products to various industries. With a commitment to innovation, sustainability, and customer satisfaction, [Company Name] remains at the forefront of the steel industry, driving its growth and success.Press Contact:[Name][Designation][Company Name][Phone][Email]

Innovative Induction Furnace Tech Enhances Steel Manufacturing Efficiency

Title: Revolutionary Induction Arc Furnace: A Breakthrough in Modern Steel ProductionSubtitle: Company X Introduces Cutting-Edge Technology Set to Revolutionize the Steel IndustryDate: [Date][City], [State] - Company X, a global leader in innovative industrial solutions, has unveiled its latest breakthrough in steel production technology - the Induction Arc Furnace. This groundbreaking invention promises to revolutionize the steel manufacturing process, offering numerous advantages over traditional methods. The Induction Arc Furnace is set to become a game-changer in the industry, significantly improving efficiency, reducing environmental impact, and boosting overall productivity.The Induction Arc Furnace employs a unique combination of advanced induction heating technology and arc furnace principles. By merging the most effective features of both processes, Company X has developed a highly efficient furnace that surpasses traditional methods in multiple ways. One of the most significant benefits of the Induction Arc Furnace is its exceptional energy efficiency. Unlike conventional steel production, which heavily relies on fossil fuels, this new technology utilizes electricity as the primary energy source. As a result, it significantly reduces carbon emissions and minimizes the industry's overall environmental impact. The furnace also boasts an incredibly high power factor, ensuring optimal energy utilization, further enhancing its sustainability and cost-effectiveness.The technological advancements embedded within the Induction Arc Furnace also enable rapid melting and precise temperature control. Traditional methods often require an extended period to heat the raw materials to the desired temperature. However, the Induction Arc Furnace excels in this aspect, efficiently melting metal charges in a matter of minutes. This accelerated process not only saves valuable production time but also allows for greater flexibility and responsiveness in meeting market demands.Furthermore, the advanced temperature control mechanisms incorporated in the furnace optimizes the steel manufacturing process. The precise regulation of temperature ensures consistent product quality, reducing the risk of imperfections and increasing overall yield. This level of accuracy is vital in meeting stringent industry standards and client specifications, making the Induction Arc Furnace an attractive solution for steel manufacturers worldwide.The Induction Arc Furnace is also highly versatile, capable of processing a vast array of steel materials. This flexibility allows manufacturers to utilize various metal scrap types and grades, reducing waste and contributing to a more sustainable production cycle. The furnace's adaptability and compatibility with countless steel alloys make it a valuable tool for diverse industries, including automotive, construction, and aerospace.To accompany this innovative technology, Company X provides comprehensive technical support and expertise. Through its team of highly skilled engineers, the firm offers installation, training, and ongoing maintenance services. This commitment to customer satisfaction ensures seamless integration of the Induction Arc Furnace into existing manufacturing processes, allowing clients to fully leverage its capabilities and optimize their production cycles.Eager to penetrate global markets, Company X has already received overwhelming interest from major steel manufacturers worldwide. The company's technologically advanced Induction Arc Furnace presents a compelling alternative to traditional steel production methods, offering enhanced efficiency, reduced environmental impact, and greater cost-effectiveness.The introduction of this revolutionary furnace sets a new benchmark in modern steel manufacturing. Company X's commitment to continuous innovation reinforces its position as a trusted partner in shaping the future of the industry. With this pioneering technology, the steel manufacturing sector takes a significant step forward, aligning itself with sustainable practices and meeting the evolving needs of a rapidly changing world.As the global steel industry strives towards more efficient and environmentally responsible operations, the Induction Arc Furnace offers a beacon of hope and progress. Company X's breakthrough technology will undoubtedly reshape the steel production landscape, setting new industry standards for quality, efficiency, and sustainability.In conclusion, the Induction Arc Furnace represents a pivotal moment in the steel industry's evolution. With its superior efficiency, reduced environmental impact, and unparalleled flexibility, this groundbreaking technology will catalyze change, redefine process effectiveness, and accelerate progression towards a greener and more progressive future.

Top-rated Induction Furnace Factory Gains Industry Recognition

[Company Name] Emerges as a Leading Induction Furnace Manufacturer[City], [Date] - [Company Name], a renowned manufacturer in the industrial sector, is making waves in the market with its top-notch induction furnace production. With a commitment to quality and innovation, the company has positioned itself as the best induction furnace factory in the region.Induction furnaces play a crucial role in various industries, including metal smelting, foundries, and steel manufacturing. These furnaces utilize the principle of electromagnetic induction to heat and melt metals, providing efficient and reliable results. [Company Name] has mastered the art of manufacturing these furnaces, delivering cutting-edge technology and exceptional performance.With a state-of-the-art production facility, [Company Name] stands out for its meticulous attention to detail in every step of the manufacturing process. The company prioritizes quality control, using the finest materials and implementing rigorous testing procedures to ensure the longevity and performance of its induction furnaces."Our mission is to revolutionize the industry by consistently providing premium-quality induction furnaces that exceed our customers' expectations," said [Spokesperson's Name], the company's spokesperson. "We combine advanced technology with skilled craftsmanship to deliver products that stand the test of time."[Company Name] offers a diverse range of induction furnaces tailored to meet the unique needs of various industries. Whether it's medium-frequency furnaces, high-frequency furnaces, or custom-built solutions, the company's product lineup is designed to cater to a wide range of applications. These furnaces offer exceptional energy efficiency, enabling businesses to reduce operational costs while optimizing productivity.Furthermore, the company's commitment to environmental sustainability sets it apart from its competitors. By utilizing specialized features such as advanced insulation and efficient cooling systems, [Company Name]'s induction furnaces minimize energy wastage and reduce carbon emissions, contributing to a greener and cleaner environment.The success of [Company Name] lies not only in its cutting-edge products but also in its team of highly skilled professionals. From engineers to technicians, the company's workforce brings a wealth of expertise and experience to the table. This dedicated team ensures seamless integration of technology and craftsmanship, resulting in reliable and efficient induction furnaces.To cater to the diverse requirements of its clientele, [Company Name] offers exemplary after-sales service and technical support. The company focuses on building long-term relationships with its customers, providing prompt assistance, spare parts, and maintenance services whenever necessary.As the demand for induction furnaces continues to soar, [Company Name] aims to expand its reach beyond the local market. The company has started exporting its products to international markets, gaining recognition for its dedication to quality and customer satisfaction. A growing list of satisfied clients worldwide is a testament to [Company Name]'s commitment to excellence.In conclusion, [Company Name] has emerged as the best induction furnace factory in the industry, combining cutting-edge technology, skilled craftsmanship, and a customer-centric approach. With its unwavering commitment to quality and a vision for innovation, [Company Name] continues to redefine the standards of induction furnace manufacturing. As the company expands its global footprint, it is set to leave an indelible mark on the industry, securing its position as a market leader for years to come.

Top Suppliers of High-Quality Copper Scrap Melting Furnaces for Various Industries

Title: Leading Copper Scrap Melting Furnace Suppliers Revolutionize Smelting IndustryIntroductionThe smelting industry forms a crucial link in the global manufacturing supply chain, supporting numerous sectors such as automotive, construction, electrical, and electronics. Within this industry, copper scrap melting furnaces play a pivotal role in the efficient recycling and refining of copper materials, thereby reducing environmental impact and conserving valuable resources. Amidst growing demand for sustainable and technologically advanced solutions, a host of influential suppliers have emerged as leaders in the market. In this article, we will explore the innovative offerings of several prominent copper scrap melting furnace suppliers and their contributions to the industry's development.Supplier 1: (Name removed)Renowned for its cutting-edge technology and extensive industry expertise, Supplier 1 has indubitably made its mark in the global copper scrap melting furnace market. Equipped with a diverse portfolio, the company delivers a range of high-quality furnaces tailored to the varying needs of its clientele. These furnaces exhibit remarkable energy efficiency, thus reducing electricity costs and minimizing carbon emissions. Supplier 1's commitment to research and development continually drives groundbreaking advancements, ensuring its customers benefit from the latest innovations in the field.Supplier 1's furnaces are known for their exceptional heat transfer capabilities, enabling quick and precise melting of copper scrap. This not only improves productivity but also results in reduced material wastage. The company's dedication to supporting eco-conscious practices is evident through its use of state-of-the-art pollution control mechanisms, ensuring compliance with stringent environmental regulations. By offering highly efficient exhaust gas purification systems, Supplier 1 contributes to a sustainable smelting process while minimizing the impact on local communities.Supplier 2: (Name removed)Another industry leader, Supplier 2, has been at the forefront of providing reliable and superior copper melting furnace solutions to its global clientele. With a proven track record of delivering high-performance products, Supplier 2 has gained a reputation for its commitment to quality, efficiency, and customer satisfaction. Their furnaces are meticulously designed to facilitate easy operation and maintenance, ensuring minimal downtime for businesses.Supplier 2 embraces advanced technology to optimize the melting process, resulting in higher productivity and enhanced flexibility for users. The company's dedication to environmental stewardship is reflected in its utilization of cutting-edge filtration systems that effectively remove harmful particulates, minimizing air pollution. Furthermore, Supplier 2's continuous focus on energy efficiency allows customers to reduce energy consumption, benefiting both their bottom line and the planet.Supplier 3: (Name removed)Supplier 3 is an eminent supplier in the copper scrap melting furnace market, offering a broad range of technologically advanced furnaces that cater to the diverse needs of its global clientele. The company’s commitment to sustainability is evident in its furnaces, which are designed to minimize energy consumption while maximizing operational efficiency. Supplier 3's revolutionary heat control technology ensures precise temperature management during the melting process, allowing for greater consistency in the final product.Moreover, Supplier 3 emphasizes safety as a paramount concern, integrating robust safety features into its furnaces for the protection of workers. With comprehensive control systems and real-time monitoring capabilities, customers can effectively manage and optimize their production processes. By prioritizing innovation and reliability, Supplier 3 has established itself as a trusted partner in the copper smelting industry.ConclusionIn an era of rapid industrialization and growing environmental concerns, the contributions made by leading copper scrap melting furnace suppliers cannot be overstated. Through continuous innovation and commitment to sustainability, these companies are transforming the smelting industry, paving the way for a greener and more efficient future. By leveraging advanced technologies and stringent quality control measures, these suppliers ensure that their customers enjoy enhanced productivity, reduced operational costs, and a reduced environmental footprint. As the demand for copper continues to rise, these influential leaders will undoubtedly play a critical role in shaping a more sustainable and prosperous industry.

Guide to Buying the Best Melting Furnace for Aluminum Scrap Recycling

Aluminum Scrap Melting Furnace Revolutionizes Recycling Industry: A Breakthrough Innovation[Company Name], a leading pioneer in the field of recycling solutions, has recently unveiled their latest innovation, the Aluminum Scrap Melting Furnace. With the goal of revolutionizing the recycling industry, this state-of-the-art furnace is set to redefine the process of aluminum scrap melting and significantly enhance the efficiency and sustainability of recycling aluminum.Sustainability and environmental consciousness have become increasingly vital concerns in recent years. The call for more efficient recycling methods has grown louder, with aluminum being one of the most widely recycled materials due to its high value and endless recyclability. [Company Name] recognizes the urgency to improve and optimize the recycling process, leading them to develop the Aluminum Scrap Melting Furnace.The Aluminum Scrap Melting Furnace is designed to provide an innovative solution to the challenges faced by conventional melting processes. By combining advanced technology and groundbreaking engineering, [Company Name] has developed a furnace that is capable of melting aluminum scrap at an unprecedented speed while minimizing energy consumption.One of the primary features that set this furnace apart is its advanced heating system. Unlike traditional furnaces that rely on fossil fuels, the Aluminum Scrap Melting Furnace utilizes a cutting-edge electric heating system. This not only makes the process more environmentally friendly by reducing greenhouse gas emissions, but also provides enhanced precision and control over the melting process.The furnace is equipped with a sophisticated control panel, allowing operators to set and monitor the required temperature accurately. The efficiency of this furnace is further elevated by automated temperature control and feedback mechanisms, ensuring optimal melting conditions and reducing the risk of overheating or wastage.Moreover, the Aluminum Scrap Melting Furnace is engineered to accommodate a wide range of aluminum scrap, from various alloys to different shapes and sizes. Its versatility enables recycling facilities to process diverse types of scrap efficiently, maximizing the utilization of resources and reducing the amount of aluminum ending up in landfills.The furnace's ergonomic design also aims to improve the overall working conditions in recycling plants. With user-friendly features and advanced safety mechanisms, such as automated lid opening and closing, operators can carry out their tasks with ease while minimizing the risk of accidents or injuries.In addition to its remarkable functionality, the Aluminum Scrap Melting Furnace boasts a compact and modular design. This allows for easy installation and integration into existing recycling facilities, minimizing downtime and increasing operational efficiency. The furnace's modular nature also enables scalability, providing recycling plants the flexibility to expand their capacity as needed without significant disruptions.[Company Name]'s Aluminum Scrap Melting Furnace is not only a game-changer for recycling facilities but also a substantial step towards a more sustainable future. By improving the efficiency and effectiveness of aluminum scrap melting, this furnace contributes to the conservation of valuable resources and reduces the environmental impact of the recycling process.With concerns about climate change and the importance of transitioning to a circular economy, the Aluminum Scrap Melting Furnace represents a significant breakthrough in recycling technology. [Company Name] continues to push the boundaries of innovation, setting new benchmarks for sustainability and resource optimization, and solidifying its position as a leader in the recycling industry.In conclusion, the Aluminum Scrap Melting Furnace developed by [Company Name] is set to revolutionize the recycling industry. This cutting-edge furnace enhances the efficiency and sustainability of aluminum scrap melting, utilizing advanced electric heating technology, precision control mechanisms, and modular design. By implementing this innovative solution, recycling facilities can significantly reduce energy consumption, minimize waste, and contribute to a greener and more sustainable future.

Everything You Need to Know About Efficient Lead Smelting Furnaces

In recent years, the Lead Smelting Furnace (need remove brand name) has become an important tool for companies looking to maximize their metal production efficiency. With its advanced technology and innovative design, this furnace has become a leading choice for businesses looking to increase their lead production capacity.The Lead Smelting Furnace (need remove brand name) is a state-of-the-art furnace that has been designed specifically for the smelting of lead ores. The furnace is capable of processing a wide range of different types of lead ores, including galena, cerussite, and anglesite. This makes it an ideal choice for companies looking to increase their production of lead-based products.One of the key features of the Lead Smelting Furnace (need remove brand name) is its advanced smelting technology. The furnace utilizes a highly efficient smelting process that is designed to maximize the amount of lead that can be extracted from the ore. This results in higher yields and a more efficient production process overall.In addition to its advanced smelting technology, the Lead Smelting Furnace (need remove brand name) also features an innovative design that makes it easy to use and maintain. The furnace is designed with a user-friendly interface that allows operators to easily control and monitor the smelting process. This helps to minimize downtime and ensure that the furnace is always operating at peak efficiency.The Lead Smelting Furnace (need remove brand name) is also designed to be highly durable and long-lasting. The furnace is constructed from high-quality materials that are designed to withstand the rigors of continuous use. This helps to minimize maintenance costs and ensures that the furnace will continue to operate reliably for many years.Perhaps one of the most important benefits of the Lead Smelting Furnace (need remove brand name) is its ability to help companies minimize their environmental impact. The furnace is designed to be highly efficient, which reduces the amount of energy required to smelt lead ores. This helps to minimize greenhouse gas emissions and reduce a company's environmental footprint.Overall, the Lead Smelting Furnace (need remove brand name) is an excellent choice for companies looking to increase their lead production capacity while minimizing their environmental impact. Its advanced technology, innovative design, and user-friendly interface make it a leading choice among manufacturers worldwide.In recent years, demand for the Lead Smelting Furnace (need remove brand name) has grown significantly, with more and more companies turning to this furnace to help them maximize their lead production efficiency. As a result, the manufacturer of the furnace has also experienced significant growth in recent years.The company behind the Lead Smelting Furnace (need remove brand name) is a leading manufacturer of smelting furnaces and other metal processing equipment. With decades of experience in the industry, the company has established a reputation for producing high-quality, reliable equipment that delivers consistent performance over the long term.One of the key factors that sets the company apart from its competitors is its commitment to innovation. The company invests heavily in research and development, constantly working to improve its products and develop new technologies that can help its customers increase their productivity and efficiency.In addition to its commitment to innovation, the company is also dedicated to providing excellent customer service. The company has a team of highly trained technicians and support staff who are available to assist customers with any questions or concerns they may have about their equipment. This helps to ensure that customers get the most out of their investment in the Lead Smelting Furnace (need remove brand name) and other products.Overall, the Lead Smelting Furnace (need remove brand name) and the company behind it are excellent examples of the kind of innovative, customer-focused companies that are driving growth and progress in the metal processing industry. With its advanced technology, efficient design, and commitment to customer service, the Lead Smelting Furnace (need remove brand name) is setting a new standard for excellence in the industry.